Last week I spoke on the evolution of the digital supply chains and my vision for Supply Chain 2020 at the World Trade Group Event in Miami. I was the last speaker at the event. There were many cancellations in the program, and as a result, I questioned why I had come. However, it turned out OK. The audience stayed for the presentation, and following the event there were many spirited debates at the restaurant bar on the content. I had touched some nerves with my five predictions for 2020:

- Digital, Outside-in Value Networks. We are beginning to design and implement outside-in processes which will fuel growth agendas. These will be the foundation of digital supply chain thinking and will redefine business in the next decade.

- Learning Systems. Technologies are changing. In five years I believe we will have supply chain planning systems that learn while we sleep.

- Network of Networks. Leaders will work with technology innovators to build the Network of Networks, ensuring interoperability between networks.

- Master Data Is No Longer a Barrier. Cognitive learning and rules-based ontologies will redefine master data management technologies making them obsolete.

- Redefinition of Talent. Dealing with the talent shortage in emerging economies will redefine human resource policies and industry consortia programs.

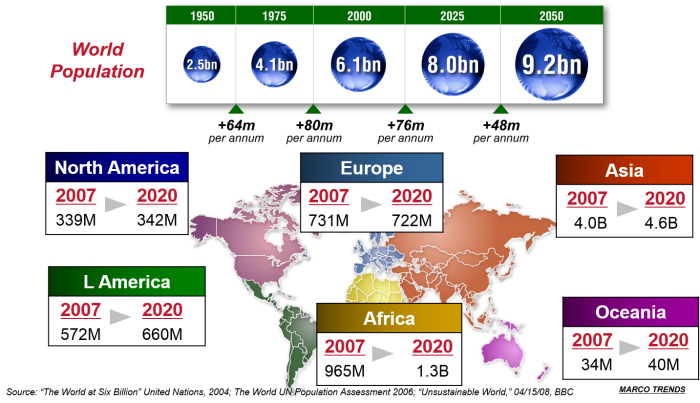

I believe the demographics shifts shown in Figure 1 will transform Supply Chain 2020. I also believe that growth in Asia and Africa will spur new thinking in supply chain processes for the use of mobility and sensor data.

Figure 1. Supply Chain 2020

While the companies in the post event discussions liked the predictions and were ready to take the jump, they struggled on the how. My take-away? It is hard to jump when shackled with a ball and chain. How so? Let me explain.

Let’s start with a definition. A ball and chain is a restraint placed on a prisoner’s leg to prevent flight. Used from the 17th century until the late mid-20th century, a ball and chain found in 2009 in the United Kingdom from the 17th century was an 18 pound ball, six inches in diameter. A 35-inch chain connected it to the prisoner’s leg.

Making the Leap to the Digital Supply Chain

2020 i s four years away. It is just around the corner. The clock will move quickly. There are some positives: in 2016, over 60% of supply chain leaders are embracing cloud-based solutions, and 45% are increasing their spend in supply chain management solutions. So why am I worried and writing a post about a ball and chain? There are three reasons or barriers:

s four years away. It is just around the corner. The clock will move quickly. There are some positives: in 2016, over 60% of supply chain leaders are embracing cloud-based solutions, and 45% are increasing their spend in supply chain management solutions. So why am I worried and writing a post about a ball and chain? There are three reasons or barriers:

A Singular Focus on ERP. As you can see in Figure 2, today ERP programs are consuming most companies. While I believe that an ERP program ensures a global system of record for transactions, I do not believe it is the backbone for the digital, outside-in supply chain. ERP is inside-out. By definition, it is not outside-in. Instead, the data model is inside-out. The goal of ERP is enterprise automation. Canonical networks, based on many-to-many data models, will be the backbone of future value network interactions.

Figure 2. Focus of Spending in 2016

My recommendation: Implement ERP well the first time and recognize that it is essential for enterprise efficiency, but that it is not the backbone for value networks or the digital pivot. Try to free up resources that worked on ERP to embrace new forms of analytics.

The Most Efficient Supply Chain Is Not the Most Effective. Within manufacturing companies with business process outsourcing, as the number of supply chain leaders decreased, power shifted to financial teams. There is continuous pressure on costs. The singular pressure on costs can throw the supply chain out of balance and cause many companies to forget that the most efficient supply chain (with the lowest cost per case) is seldom the most effective supply chain. Why?

The issue is that costs need to be continually balanced with customer service, and inventory programs, against a business strategy. If the supply chain has high volumes and high demand volatility (like vaccines, suntan lotion, bathing suits, seasonal foods), creating an efficient supply chain with the lowest cost, and reducing costs in continuous improvement programs without attention to the balance with customer service and inventory, is detrimental.

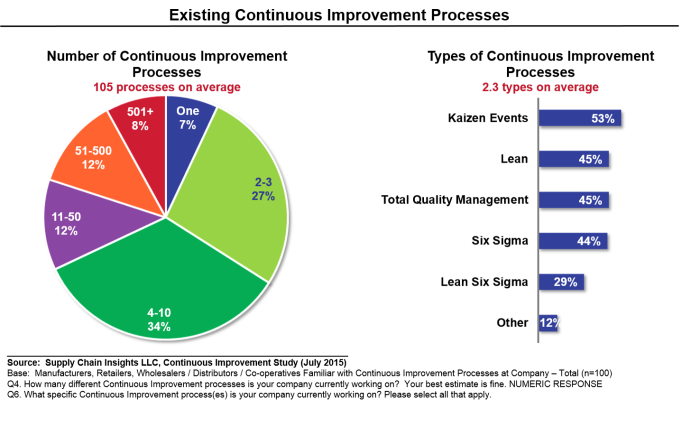

As shown in Figure 3, most companies have over 100 continuous improvement programs operating simultaneously; and with this many programs operating simultaneously, most companies struggle to balance cost, customer service, and inventory against the strategy. Getting there requires support by finance and a clear cross-functional understanding of supply chain management.

Figure 3. Continuous Improvement Programs

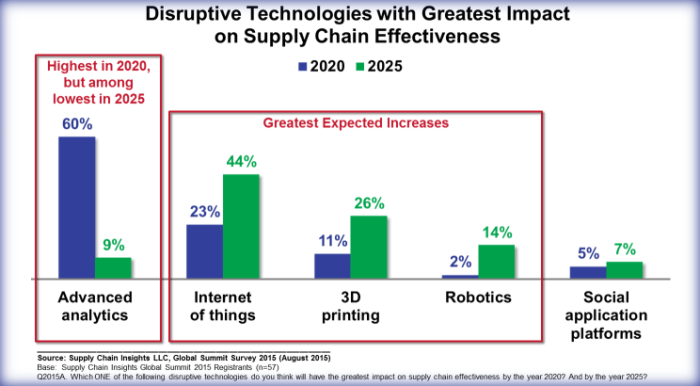

Guide the discussion from cost to value. Then start to map outside-in processes and embrace the confluence of technologies to accelerate your journey. At our recent Supply Chain Insights Global Summit, the attendees were focused on embracing the confluence of technologies shown in Figure 4.

Figure 4: Embracing the Confluence of Technologies to Drive the Digital Pivot

Recommendation: Be very clear on supply chain strategy and what is needed to drive success in customer service. Do not cut cost for the sake of cutting cost. Instead, try to focus the organization on cutting cost while driving a balanced metrics portfolio that includes inventory turns, customer service targets, Return on Invested Capital and growth. Use the funds from continuous improvement programs to self-fund digital programs. With IT budgets strapped with continuous upgrades of licensed systems, the self-funding of digital programs—cloud based software, sensors, new forms of analytics, visibility networks—may be the only way to stimulate the movement from inside-out to outside-in processes.

We Have Best Practices. Many traditional supply chain leaders believe that if we just continue to invest in continuously improving traditional processes, that progress can happen and the processes can become outside-in. What many do not realize is building digital processes and defining outside-in processes is a step change, not an evolution. (For more on this topic, reference my blogs on the building of the digital supply chain.)

If you run into this argument, use Figure 5 to support your argument. Nine out of ten supply chains are stuck: the companies are unable to make improvement at the intersection of operating margins and inventory turns. It is time to make a change.

Figure 5. Current State of Supply Chain

To make the leap we must change paradigms, invest in new technologies, and drive a process redefinition. I find this exciting, but it is hard to make the jump with the ball and chain of legacy thinking and investments. What do you think? How do you think that we build the digital supply chain and power outside-in processes?

For more join Beet Fusion!

Two weeks ago we launched our new community, Beet Fusion. Within ten days 470 supply chain leaders joined the community. Our goal is for Beet Fusion to have the features of LinkedIn, Monster, Yelp, and Facebook for the Supply Chain Community. Why the name Beet Fusion? It’s the Superfood for the supply chain.

The community is currently in Open Beta. So when you join, try to stress test the community and let us know your suggestions and concerns. Be patient. It will take us time to work out the issues. To drive improvements, we also would love your feedback in the Beta Tester’s forum.

About the Author:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora wrote the books Supply Chain Metrics That Matter and Bricks Matter, and is working on her third book, Leadership Matters. As a frequent contributor of supply chain content to the industry, Lora writes by-line monthly columns for SCM Quarterly, Consumer Goods Technology, Supply Chain Movement and Supply Chain Brain. She also actively blogs on her Supply Chain Insights website, for Linkedin, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research at Temple, or knitting and quilting for her new granddaughter. In between writing and training, Lora is actively doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. She thinks that we are never too old to learn or to push an organization harder to improve performance.

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora wrote the books Supply Chain Metrics That Matter and Bricks Matter, and is working on her third book, Leadership Matters. As a frequent contributor of supply chain content to the industry, Lora writes by-line monthly columns for SCM Quarterly, Consumer Goods Technology, Supply Chain Movement and Supply Chain Brain. She also actively blogs on her Supply Chain Insights website, for Linkedin, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research at Temple, or knitting and quilting for her new granddaughter. In between writing and training, Lora is actively doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. She thinks that we are never too old to learn or to push an organization harder to improve performance.