Last week, I spoke at the Inventory Management IE Event (http://www.theiegroup.com/Inventory_Optimization/Overview.html) in Dallas. To prepare, I worked with my speech coach. Her guidance was to focus on one MAIN theme. This is so hard for me to do. I find the world of supply chain management so EXCITING, that I want to tell the world EVERYTHING. So, fought my instincts and applied the coach’s counseling and polished my presentation to focus on just one BIG IDEA. The speech focused on my observation that supply chain leaders focus on form and function of inventory not just inventory levels (http://www.slideshare.net/Altimeter/inventory-presentation-sent-to-ie-group-version2-9881657).

During the presentation, I thought that the speech was going well. While I was not Tina Fey, I got a few laughs, and the audience was responding. However, at the end of my presentation, a man on the third row raised his hand and said, “I did not understand anything that you just said….” <Bummer, I thought to myself.> I sighed and asked him his background. His response was “…that he works in finance.” Clearly, I thought that I was speaking to a supply chain audience, but I found the lack of understanding by the members from financial teams to be thought provoking.

I mulled the response on my airplane ride, and smiled when I got a linkedin invitation from an attendee. Her email stated, “I loved your presentation today. I have been working hard to help our executives understand the principles of form and function of inventory, but it is difficult because most financial groups do not understand the principles of supply chain. You did a great job.” I passed the note to my speech coach and began thinking more deeply about the issue that I had just observed. A cross-understanding of inventory–the drivers and barriers–is needed before organizations can move forward on supply chain excellence. Most organizations are stuck.

What is the Form and Function of Inventory?

Inventory levels are flat year-over-year in our supply chains. With rising volatility, this is even tough to sustain. While technology and supply chain practices helped us push the levels of inventory down following Y2K, the progress has leveled out ( Reference post Let’s Put Working Capital to Work http://www.supplychainshaman.com/page/3/?s=inventory). My observation is that while most companies focus on the level of inventory–how much inventory is the right amount–for their supply chain, supply chain leaders go one step further to focus on form and function of inventory. And, as I experienced at the conference, these concepts are not well understood.

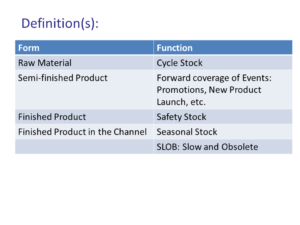

The form of inventory is the state in which it is stored. Inventory can be stored as raw materials, semi-finished goods and as a finished good or final assembly. The further back in the supply chain that inventory is stored (e.g. raw materials), the greater the supply chain flexibility.

The function of inventory is the role that the inventory plays in the supply chain. There are many forms–cycle stock, seasonal inventory, event pre-builds –that need to be managed. See figure 1 for an overview.

An area of opportunity for most companies that I work with is cycle stock. While most companies talk of safety stock (the decision to hold inventory to buffer supply and demand variability), I find that few companies understand the principles of cycle stock. Cycle stock, the inventory that is necessary to cycle through products or from manufacturing to distribution cycles is often a missed opportunity. Or decisions are made that increase the need for cycle stock without thinking through the impact…. Let me give you recent examples. Recently, I visited a client and toured their new manufacturing plant. They were very proud of their new facility; and were surprised when I asked them about the impact of the decision to change the manufacturing hold time from one day to two weeks. In short, they had not thought about the impact on warehousing or inventory carrying costs. Likewise, I visited a client that had implemented a step-change improvement in manufacturing line speed, but with long changeovers resulting in longer runs. When I asked them about the impact on cycle stock, they had not thought about it. Similarly, I visited a company that had changed outsourcing strategies from the Caribbean to Mexico. When I asked about the longer shipments and the impact on cycle stock, they were surprised. Also, like a dysfunctional family, I find very few companies willing to talk about their SLOW and OBSOLETE inventories (often referred to as SLOB).

Where can I get Help?

There are a lot of technology solutions in the market to improve inventory optimization. While some focus on the level of inventory (the left hand side of figure 2), others help with form and function of inventory. This industry segment, in many ways, is a fruit basket. Many variants of deeper optimization to help improve the decision on inventory. In figure 2, I share my view of the industry.

How do I sell the Idea?

The lasting impact happens when people understand the impact of supply chain decisions on inventory and working capital. The next step is to tie them to incentives.

A successful approach for many is the use of the Beer Game simulation to help ground in the concepts of demand uncertainty followed by a competitive team activity where network strategy tools are used in a case study. When teams are asked to design a supply chain for excellence and make trade-offs on efficiency, responsiveness and agility, they can see the impacts on working capital. This hands on experience helps people to see the trade-offs (that often remain elusive in real-life), and to discover the nuances of supply chain excellence.

It is a complex system, and I think the concepts are best taught through experimental learning. And, based on the feedback that I got at the conference in Atlanta, for most, it needs to happen soon. I am constantly surprised in my travels how little most financial teams understand about the trade-offs of supply chain planning and what defines supply chain excellence.

Today, I am speaking on this topic at the Chief Supply Chain Officer’s conference in Chicago. Hopefully, the response this time will not be heh? I will let you know. And, please share any techniques that have worked for you in on the blog.