To drive global scale, companies need to design the supply chain to buy globally and execute locally. Not many companies have cracked this code. The design of the supply chain is fundamental to making this happen. Managing complexity is key. In our interview of the Supply Chains to Admire Winners, we found a unique approach at Carter’s. Here we share the story.

To drive global scale, companies need to design the supply chain to buy globally and execute locally. Not many companies have cracked this code. The design of the supply chain is fundamental to making this happen. Managing complexity is key. In our interview of the Supply Chains to Admire Winners, we found a unique approach at Carter’s. Here we share the story.

About Carter’s

Carter’s, Inc., also known as the William Carter Company, is the leading brand of children’s clothing, gifts and accessories in America. The company sells more than ten products for every child born in the U.S. Based on a heritage of quality and innovation, the designs earned the trust in generations of families. Sold under the Carter’s and OshKosh B’gosh brands, the garments are merchandised at 600 company-owned retail stores, as well as thousands of national department stores, and some of the country’s largest retailers, like Babies ‘R Us®, Belk®, Bon-ton®, JCPenney®, Kohl’s®, Macy’s®, and Sears®. Brands include Carters, OshKosh B’gosh, Child of Mine, Just One You, and Genuine Kids.

The operations are complex. To satisfy demand, Carter’s operates out of five domestic and international distribution centers handling approximately 31,000 items at a location (SKUs). Shipping approximately 400 million selling units consisting of 700 million manufactured units per year, Carter’s employs about 4,000 employees at its peak. The company leverages globally sourcing strategies to buy products at a lower cost and then deploys some unique process logic to drive mass customization for retailers.

For this case study we interviewed Peter Smith, currently the EVP of Supply Chain for Carter’s. The company is one of 15 winners in the 2016 Supply Chains to Admire Research. We first met Peter when he was a Global Vice President Supply Chain for VF Corporation in Europe. In this role he supported the different businesses (12 in Europe and 11 in Asia) for all aspects of the Supply Chain; but Peter did not have direct Asia Sourcing/manufacturing accountability. One of Peter’s motivations to leave VF Corporation was directly management responsibility to run a successful brand/business.

For this case study we interviewed Peter Smith, currently the EVP of Supply Chain for Carter’s. The company is one of 15 winners in the 2016 Supply Chains to Admire Research. We first met Peter when he was a Global Vice President Supply Chain for VF Corporation in Europe. In this role he supported the different businesses (12 in Europe and 11 in Asia) for all aspects of the Supply Chain; but Peter did not have direct Asia Sourcing/manufacturing accountability. One of Peter’s motivations to leave VF Corporation was directly management responsibility to run a successful brand/business.

About the Supply Chains to Admire Research

Over the period of 2009-2015, only 88% of companies made improvement on the Supply Chain Metrics That Matter. (As a group, these metrics have the highest correlation to market capitalization. They include growth, inventory turns, operating margin and Return on Invested Capital (ROIC)).

Over the period of 2009-2015, only 88% of companies made improvement on the Supply Chain Metrics That Matter. (As a group, these metrics have the highest correlation to market capitalization. They include growth, inventory turns, operating margin and Return on Invested Capital (ROIC)).

As a group, public companies want to make progress to both drive and sustain metrics performance, but they cannot. To meet the criteria for the 2016 Supply Chains to Admire list, companies needed to score better than their peer group average for all of the performance metrics, while driving a higher level of improvement than 2/3 of their industry peer group.

Supply Chain to Admire Winners meet three criteria: improvement, performance and value.

- Improvement. Supply Chain Index. The Supply Chain Index measures supply chain improvement for an industry peer group. A ranking in the top 2/3 of the peer group qualifies a company for further analysis. We eliminate the lower 1/3 of companies for the period from consideration.

- Value. Price to Tangible Book Value (PTBV). This analysis determines which companies are driving the greatest value. We first throw out the outliers in the PTBV calculation. After the elimination of outliers, we include companies that are at or above the PTBV value (allowing for no more than 5% below the mean for the peer group to account for rounding errors).

- Performance on the Supply Chain Metrics That Matter. Companies passing these two tests are then analyzed against the performance factors for 2009-2015:

- Growth. Higher percentage growth than the industry average.

- Operating Margin. Greater margin performance than the industry average for the peer group for the period studied.

- Inventory Turns. Better performance in inventory turns than the peer group average for the period studied.

- Return on Invested Capital (ROIC). Higher performance on ROIC than the average for their peer group for the period.

In the analysis of the performance factors, we divided the companies into two groups:

- Supply Chains to Admire Winners. In the analysis of the performance factors of growth, operating margin, inventory turns, and Return on Invested Capital, Supply Chains to Admire winners score at or above the industry peer group average for all four of the factors. (Must be within 5% of the mean of the peer group to account for potential rounding errors.)

- Supply Chains to Admire Finalists. Companies meeting the Supply Chain Index and the PTBV criteria, but falling below the peer group averages on the performance factors, are finalists if they are no more than 10% below the industry average for three out of four of the performance factors, and no more than 25% below on any single performance factor.

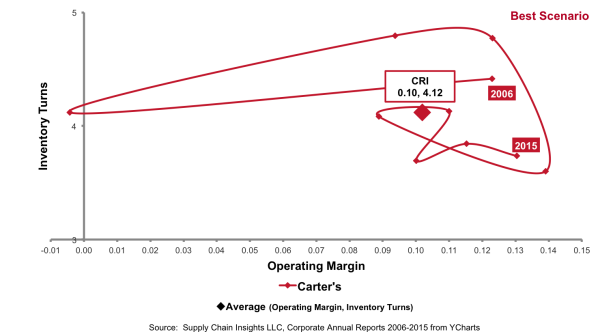

Figure 1. Orbit Chart of Carter’s: Intersection of Inventory Turns and Operation Margin for the Period of 2006-2015

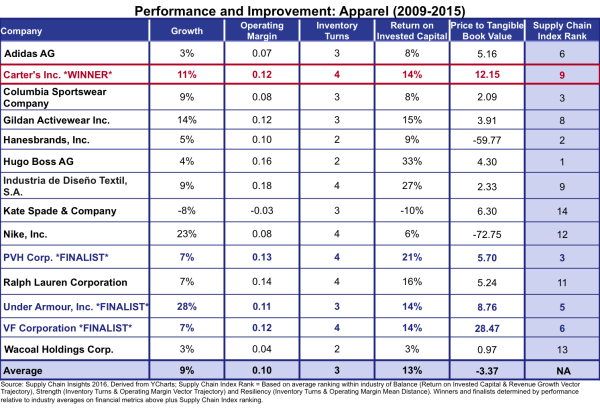

In the period of 2009-2015, Carter’s drove significant improvement in operating margin. As shown in Table 1, the averages for Carter’s for the Supply Chain Metrics That Matter are significantly better than their peer group.

Table 1. Apparel Performance and Improvement Comparison

Interview with Peter Smith, EVP Supply Chain of Carter’s, Inc.

We share this case study in a Q&A format.

You were a winner of the 2016 Supply Chains to Admire. What drove the level of improvement?

Necessity is the mother of invention. We manufacture 700 million pieces of clothing and service every channel in the U.S. along with international markets. The diversity is rising. This drove a need for complexity management and mass customization like I have not seen elsewhere. The market demand has spurred Carter’s to create strategies, systems and processes to focus on low prices and competitive market place and distribution.

Today, we do not have a single an all-knowing, all-seeing, and seamless world-class IT system. It just does not exist. This is not a place where one great killer app or technology has slayed the dragon, but the systems are malleable. Driven by the business, our teams, in IT/IS and in the business find creative ways to invent solutions. Is it elegant? No. However, it is really effective for our processes.

In my experience, technologies like SAP are rigid. It is too inflexible for us. We need agility. As a result, Carter’s runs an assemblage of systems focused on agility. They are modified collectively to deal with our complexity. A bit of magic created to deal with complexity is the leveraging of our ERP dimension code repurposed to carry information for final retailer specifications in addition to style, color, and size. We redeployed the DIM code solution for all points of distribution. This allows us to get the benefit of 1 million units PO size for leverage and manufacturing efficiency with DIM codes attached to the style defining the retail unit. We can purchase in large lots, postpone, and then pack out based on DIM Codes. This gives us both economies of scale and flexibility.

Let me explain how this works. When the units come off the final assembly line, the third-party manufacturing company applies the value added services like tagging, packaging and pack them based on the retailer’s shipment ready requirements. We pack once for the destination and 90% of the units are never touched again. Customization happens as part of the manufacturing process, not in domestic DC’s. We pull off this level of efficiency every day.

How do you manage complexity?

It is a combination of strategy, people, processes and systems. We are an international company supplying international trade. We desire and work towards postponing decisions about the allocation of finished units between our wholesale customers, the 700 retailer stores of our own and Carter’s e-com to optimize inventory utilization. Once you have put on our retail tags, you have locked in the inventory. We do things downstream to improve flexibility and inventory utilization efficiency. Multi-channel distribution requires getting the most visibility possible. Our processes strive to recognize the uncertain demand in the world we live in and make the best of that reality.

What is your next-generation supply chain strategy?

There is a significant amount of distance that we can go in what we have talked about today. We would like to get ever more granular through better postponement.

We are also trying to embrace all of the data around us. We have migrated planning and forecasting from big Excel spreadsheets to up to a cloud-based environment to process more data and data elements. We are in the early stages or using this big data environment. I am advocating the organization lean into and embrace the cloud platform and tools. Ultimately the most efficient use of inventory relies upon being able to optimize the use of the units from the individual store shelf (at a wholesale partners or in our own retail) all the back up the chain to never miss a demand signal wherever and whenever it presents itself. We looked long and hard at packaged tools and concluded there’s not enough flexibility, scalability and speed to deploy in the packaged tools in the market. We are now in an incredibly powerful system scaled for larger demands than I think we’ll throw at it but which will never limit us.

The strategy is simpler to say than to execute; but in a nutshell, it is better decisions, lots of postponement, mastering ever-increasing complexity in a leveraged way and using all the data that we can get our hands on. I think within a fairly short period of time, we will no longer see shrink-wrapped systems in our own building. I believe in the Internet of Things and see great opportunities to “connect the dots” of data that may impact demand and create opportunities for the companies that are agile enough to respond.

How do you define supply chain excellence?

When I think of Supply Chain excellence, I believe that we never miss demand. Excellence occurs when there is minimal inventory ownership, and little; but the company never misses demand. Strategically, I have declared that as Carter’s continues to grow, it is my responsibility every year to consume a smaller and smaller percentage of sales. If the supply chain total cost of ownership of sales is x, I want a downward tilting line for supply chain costs. Survival means that we must invest in big data analytics, customization, and postponement. This excites me.

Any insights on how to build next-generation supply chain talent?

We live in a world where the rate of change is the fastest I have ever seen. To stay current, we do reverse-mentoring here. I am lucky because I have reverse-mentoring with my twenty-something kids. So I get a double dose of insights into millennial thinking.

One of the distressing things about our industry is we are not mature enough to fully drink the Kool-Aid of career mapping and organizational development like I believe other FMCG companies do. I think the P&G’s of the world “manufacture” their next generation leaders. I have not seen this done well in the apparel industry.

The supply chain is so diverse in the things that we do, as an industry we are poor practitioners of building next generation leaders. Too many people get stuck in silos. Although they become subject matter experts, they are a foot wide and a mile deep. Future Supply Chain leaders , in my estimation, we need subject matter experts, or nearly so, in multiple disciplines. That happens by luck and chance or great career mapping. I like the certainty of the latter.

Manufacturing the next generation of great Supply Chain leaders is expensive and requires commitment. I think this dedicated approach to build manufacturing leadership drives winning strategies and I hope to continue to make it come to life within Carter’s.

If you had a magic wand what would you want?

It is a dedication to talent development as I spoke of before. This should start early. I am fond of the apprentice programs used in Europe and the opportunity to get exposure in business it provides. Once in a full-time role, I’d love to see the industry manufacture well-rounded talent.

On a totally different vein, a year ago there was the buzz on the Internet of Things. We suffer from buckets of data that are not easily accessible or usable in different venues. Still hard to get, collate and standardize information for forecasting. Data is hard to get, hard to believe, and hard to use. Real-time accurate data ranging from what is happening in my factories and my distribution networks to the customer point of sale. If I could connect all these dots seamlessly and in real-time, we’d ring a lot of wasted out of our industry. EDI is a failed dream in my estimation. The internet of things holds hope.

Our Take

Companies that aggressively make the pivot to buy globally and aggregate buying power can leverage lower cost strategies. The key is some mechanism like attribute-based forecasting, attach-rate planning, or postponement. The item master, and SKU-based logic, is too restrictive and constraining. Carter’s use of the DIM code and the rationalization of retailer platforms into a standard code allows Carter’s to gain both economy of scale and flexibility to differentiate for the retail.

You can hear Peter’s story directly by attending the Supply Chain Insights Global Summit on September 5-8, 2017. Peter is one of the three confirmed speakers. We will release the full program in February and start accepting registrations in January. We hope to see you there!