I try to post weekly on this blog. As I do, there is a guy on LinkedIn– let’s call him John– that replies to most of my posts. His comments are the same–he feels that I identify problems but do not adequately define the solutions. He wants answers. Fair enough I say… I do as well. However, getting there is not easy.

When I read his comments, I feel beat up, but I try to shake it off. Comes with the territory being and influencer.

While consultants know the answers (or believe they do), I believe my goal as a research analyst is to unearth new questions that should be asked (and answered together openly in the supply chain community) to improve value. There are too few places where business leaders and technologists can challenge existing paradigms together. (This is why I host training twice a year to challenge existing technology paradigms. We have 70 signed up to start the next class on February 28th. Yes, the class is now closed. I will share insights as we go along)

The Word Salad Shuffle

In the industry, I feel that there is a lot of word salad–consultants and technologists spinning words with little meaning to drive leads. I see a preponderance of reports and white papers that have lots of pages but say little.

Back to John. His comments are typically a word salad rant. He feels that based on his years of experience with a software provider, he has a whizzbang technology. Over the course of the last decade, his story is the same. He feels he has the answer for companies. In the comments, he says, “look no further.” However, his company remains small with a couple of clients. If it was an answer, why is the company not growing?

I want to help people think differently and challenge the status quo. As I analyze business results, I see that most companies are really stuck. Like a car’s tire in a snowbank going nowhere… My goal is to free their thinking.

Peeling Back the Lid on Supply Chain World Salad

In this world, where board discussions focus on eliminating waste and meeting corporate social responsibility goals, supply chain teams respond with projects like end-to-end planning, control towers, and real-time decisions. I find few realize the irony. The reason? Each concept is flawed adding to, not reducing, cost and waste.

Current approaches result in black hole automation and bullwhip amplification. The approaches add waste and increase risk when companies think that they are investing in solutions to do the opposite. Optimization engines to improve functional metric performance resulted in an exploding number of planners. Companies that I work over the last decade increased the number of planners 3-7X with no improvement in planning outcomes. In my qualitative interviews, few can answer the series of questions of, “What makes a good plan? Did you produce a good plan? How did the company perform against the plan?”

For an understanding of my concerns with the terms end-to-end planning, control towers, and real-time decisions, I link here to prior posts. I would prefer for companies to invest in the building of outside-in processes, developing supply chain design capabilities, and investment in network automation. I don’t think companies hold themselves accountable enough for the waste created by word salad. Few companies analyze planning performance despite the cost.

Definitions

Before we move to the discussion of the actions to take, let’s get clear on some definitions.

- Blackhole Automation. In most supply chain projects we follow, we see an increase in blackholes. How does this happen? The issue is data synchronization. Attempting to integrate current and stale data without recognizing the issues of data latency. The more outsourcing and instances in IT platforms, the greater the issue with data synchronization. Let’s take a couple of examples from recent calls:

- Retail Available to Promise (ATP). A major retailer has 33 instances of Manhattan. Each is customized and runs on separate servers. Rolling up a perpetual inventory signal takes eleven hours. The company was working on improving real-time ATP without consideration of the data synchronization issues. Through the use of a NoSQL unified data model, the company is able to now move data within 15-minute increments improving the data flow for inventory availability to improve allocation and ATP processing.

- Contract Manufacturing Signal Latency. In my last blog post, I shared insights on data synchronization between brand owners and contract manufacturing. In our research, we find that 32% of volume is manufactured by a third party. On average, it takes 2.8 days to get a perpetual inventory signal and 2.2 days to receive a purchase order confirmation. The average purchase order changes 3.5 times. Synchronization accounts for the data latency and the changes to the flows.

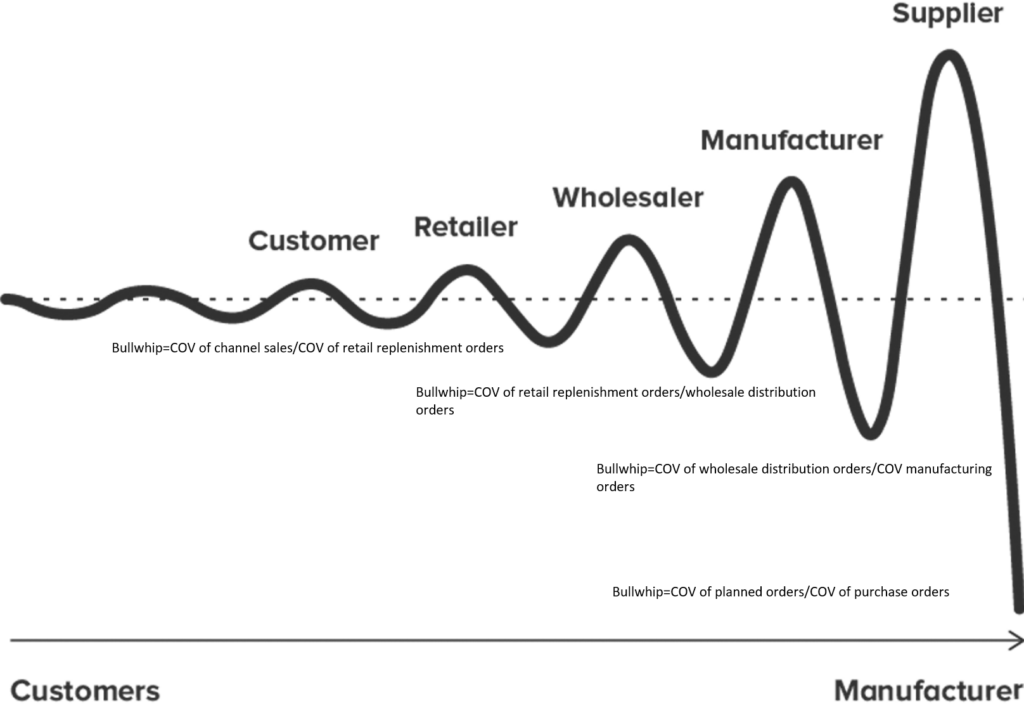

- Bullwhip Amplification. The more integration points of Advanced Planning System (APS) to Enterprise Resource Planning (ERP), the larger the bullwhip impact. (The bullwhip effect is the amplification and distortion of the demand signal at each node of the supply chain in demand translation.) A simple measurement of distortion is the ratio of Coefficient of Variation (COV). The first node is =COV of channel demand/COV of store replenishment. The second node is COV of retail replenishment/COV of the order signal to the manufacturer. The third node is the COV of the order signal to planned orders. As shown in FIgure 1, the fourth node is the COV of materials in planned orders/COV of purchase orders.

Most companies attempt to “integrate supply chain data” without accounting for the data latency in the black hole or the distortion from the bullwhip impact. Today’s advanced planning solutions do not provide a solution to address either issue. The slower the product velocity through the channel and the more nodes, the greater the bullwhip effect. The higher dependency on outsourcing and complex IT infrastructure, the greater the number of blackholes.

The Answer/Next Steps

The first step is to map and measure data latency and amplification. Take a process like order reliability and map the impact of:

- What did you know?

- When did you know it?

- What was the distortion? What is the impact of the amplification and distortion on inventory and cost? Was data latency an issue?

Armed with this knowledge, then take the next steps. To reduce data latency, and distortion:

- Invest in the Use of Channel Data. Most companies have data that they do not use. Redefine planning architectures to focus on channel flow. (In the process, minimize the use of synchronized channel data due to two-to-three-week data latency.)

- Reduce Data Latency in Networks. Automate networks with bi-directional multi-tier flow. (Think past EDI. I liken EDI to old-fashioned mail. The data latency of EDI is 10-to-24 hours.) Only 8% of companies have invested in the multi-tier network capabilities. Most depend on spreadsheets and email which adds to the issues of data latency.

- Focus on Reducing Supply Variability in Planning. Build a supply planning master data layer to capture supply variability of inbound receipts, conversion rates, yield, run-rates, and other variables. Use this data as an input to safety stock calculations, procurement decisions, and production planning.

Summary

Before a discussion on real-time data flows, control towers, and multi-tier inventory optimization, map data latency and distortion. Using a what-if planning technology perform a sensitivity analysis to understand the impact of both on inventory levels and customer service. Armed with this insight, start the discussion.

Make the argument of:

- Why are we trying to have a discussion on how to make imperfect data perfect even though it is 1-2 days old?

- How can we talk about real-time ATP when the data latency between nodes is over two days? Shouldn’t we fix the data latency issue first?

- Why tightly integrate APS to ERP if it amplifies the bullwhip impact?

- What is the impact of redefining the network to reduce nodes, parties, and product complexity?

- Why don’t we use e-commerce data with shorter demand latency to improve demand sensing?

Take the plunge.

Good luck and let me know how it goes.

And, for chuckles and grins look for John’s response to this blog post. I am sure that it will be a beautiful and eloquent series of comments.