This month, I traveled the globe helping companies understand the potential impact of technology innovation on the future of supply chain processes, I find the term “digital innovation” is a bit like tulip mania. How so? It is a fad sweeping across supply chain leadership teams. I am trying to help teams manage the hype and drive value.

This month, I traveled the globe helping companies understand the potential impact of technology innovation on the future of supply chain processes, I find the term “digital innovation” is a bit like tulip mania. How so? It is a fad sweeping across supply chain leadership teams. I am trying to help teams manage the hype and drive value.

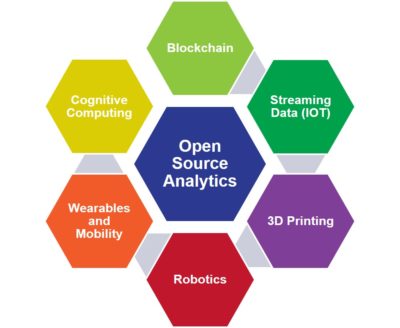

CIOs are rebranding as Digital Innovation Officers, and consultants are knocking down doors to sell digital innovation projects. Let me start with caution: buyer beware. Consultants are rebranding traditional processes and technologies as digital innovation. My advice? Sidestep the hype and drive exciting innovation with an exciting confluence of technology as shown in Figure 1.

Figure 1: The Confluence of Technologies

In my 15 years as an analyst, I have never seen more promise. However, we are in a hype cycle. Sort fact from fiction. There is a need to manage excitement and exercise caution.

Exciting Trends.

- Redefinition of the System of Record. Enterprise Resource Planning (ERP) is becoming the financial system of record, but not the supply chain system of record. With the evolution of open source technologies with schema-on-read capabilities, new forms of decision support are evolving to drive insights in the enterprise, and Blockchain is becoming the system of record for B2B. Blockchain for track & trace, supply chain finance, lineage, and supply chain visibility are exciting. I am actively working with WFP to try to fund world feeding programs with less financial leakage and provide a system of record for famine projects.

- Driving New Outcomes. The pace of best-of-breed technologies is frenetic. The pace of innovation is accelerating. ERP-agnostic architectures using machine learning and streaming data architectures are enabling new and promising capabilities. One company that I follow worked on visibility solutions for the past five years using traditional Advanced Planning and ERP capabilities. They made little progress. Then they turned to Solvoyo and used machine learning to deliver supply chain visibility in a heterogeneous environment within two months.

- Digital Manufacturing. Manufacturing Execution Systems with Data Historians have inched along over the years, but we have not been able to radically change manufacturing. Now, the use of systems like Think IQ at General Mills enable Track & Trace capabilities through manufacturing conversion points. In parallel, the work at SAS on IoT is transforming asset-intensive supply chains. The combination of wearables, IoT, and analytics is a powerful combination.

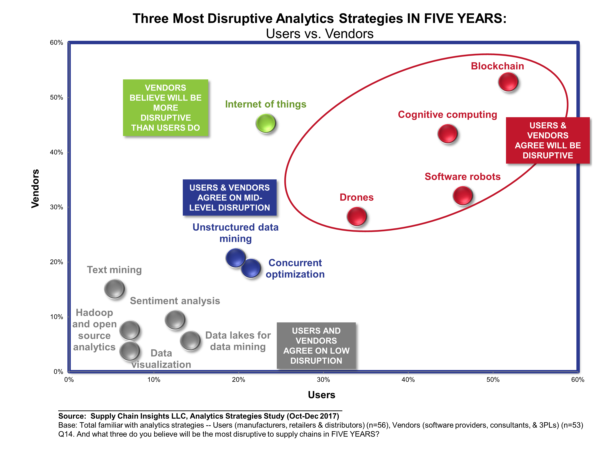

- Analytics Redefined. Driving Data-Driven Processes. Analytics is transformational. This is much deeper than data lakes and descriptive analytics. In Figure 2, I share an overview of the analytic approaches from some recent research. (Join us this month to learn about the redefinition of analytics on our monthly webinar series.) Cognitive engines will redefine decision support, machine learning is making traditional master data techniques obsolete, and data is moving now at the speed of business.

Figure 2. Disruptive Analytics Approaches

Caution.

This is not an evolution. It is a step-change in thinking and redefines IT approaches. Far from your mother’s old-fashioned supply chain processes.

Digital innovation will make much of the past obsolete. This is a tough transition for conventional ERP, APS and consulting companies. It is a bit like watching Kodak continuing to sell packaged film when they should have been redefining photography.

Digitization of signals does not drive a digital supply chain. A digital supply chain requires the use of digitization to redefine new processes. Most companies have not defined the differences between digitization and digital processes.

To have the discussion, business leaders will need to reskill and learn. This a major barrier. It is the rare leader who will raise their hand and say, “I don’t understand.” Companies need to prove the concepts and wrestle their IT teams from long and drawn-out maintenance upgrades. This will be uncomfortable. Many IT organizations define their existance from SAP and Oracle skill sets.

The implementation processes are starkly different from those of the past. Historically, projects were large and encumbered by bureaucracy. This is not the case with digital test-and-learn programs. Side-step the large implementations with traditional consulting partners and engage in design thinking. Test innovation at the edge and use stage-gate processes to drive improvement at the core.

Wrap-up

In one of my sessions last week, a client mentioned, “This is quite interesting Lora, but we do not have the time to chase bright and shiny objects. We need to focus on the basics.” I then asked, “How do you define basics?” In the end, we found that these new techniques were instrumental in improving the gaps in customer service, and reducing demand error. As a result, master data issues disappeared and visibility increased. To me, this does not sound like a bright and shiny object. It, instead, became transformational. However, it only happened because the client sidestepped the hype, invested in learning, and was open to new approaches. Defying convention may help unleash new opportunities through new technologies. These are my thoughts on a snowy day. Good luck on your journey.

I welcome your thoughts.