There is an elephant in the room. This one is white. No, it is not at your Saturday yard sale. Instead, it is deeply embedded in Information Technology (IT) strategies. You probably built it with sweat and tears. It was most likely purchased as part of a strategy to build an integrated end-to-end supply chain. It is ERP.

What is a white elephant? A white elephant is an idiom, a figurative expression, that extends beyond its literal meaning. A white elephant is a valuable possession; but is one that an owner cannot dispose of and whose cost (particularly the cost of upkeep) is out of proportion to its usefulness or worth. Resonate?

Yes, we have a Bridge to Nowhere

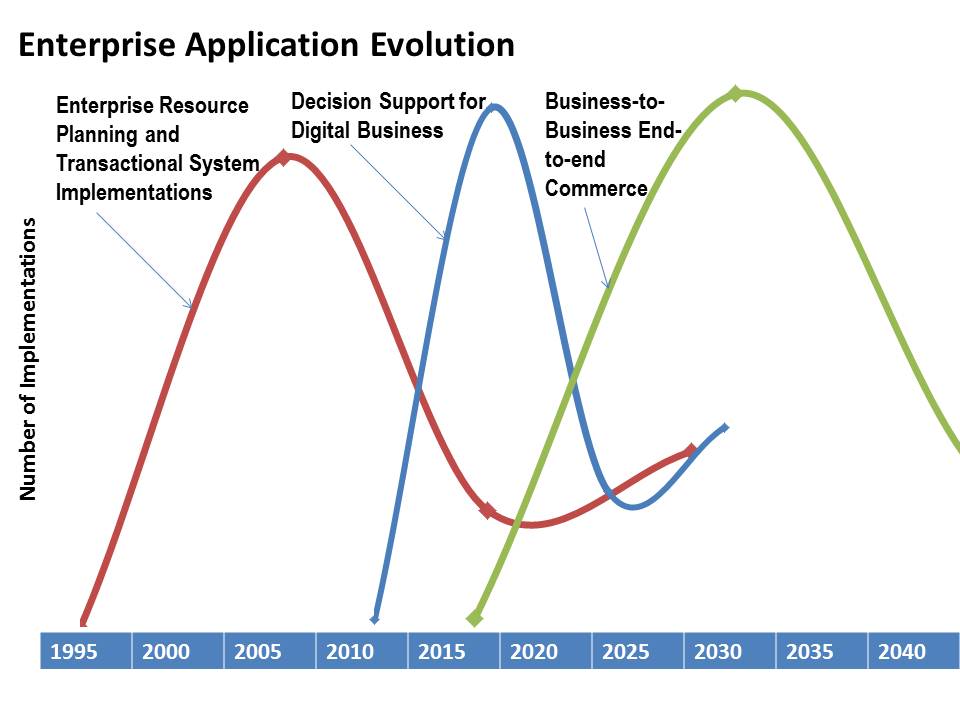

If you ask nine out ten consultants how to implement an integrated end-to-end supply chain project? The response is start with Enterprise Resource Planning (ERP) as the first step. The beauty of ERP is that it is a pre-packaged, proven solution that improves transactional efficiency. It is effective in automating order-to-cash, procure-to-pay, and a common code of accounts. No one questions that it has improved enterprise efficiency; however, the most efficient supply chain is not the most effective.

No doubt about it, supply chain transactional efficiency is a requirement for supply chain excellence, but the conventional a hub and spoke ERP architecture with a tightly integrated SCP module cannot deliver an integrated end-to-end supply chain. Companies have gone astray with tightly coupled predictive analytics– Supply Chain Planning (SCP), Product Lifecycle Management (PLM), and Supplier Relationship Management (SRM)– to the ERP backbone. This architecture misses five elements that are essential for delivery of the successful integrated end-to-end supply chain:

1) Need to start outside-in. Not inside-out. While ERP drives the effectiveness of enterprise transactions, it falls short on translating true customer requirements or supplier capabilities. It lacks the receptors. We will never achieve supply chain signal synchronization working from the inside out. Instead, we must start with the requirements of the customer’s customer and work backwards translating the requirements to the suppliers’ supplier.

Key to this evolution is the inclusion of demand sensing, demand translation and demand shaping in a demand visibility signal that can translate demand requirements with minimal latency across the supply chain. Traditional forecasting methodologies are just not up to the task, and the techniques in Materials Requirements Planning (MRP) and Distribution Requirements Planning (DRP) distorts and amplifies the demand signal. We need technology to reduce, not amplify the bullwhip effect.

2) We started with the wrong goal to get the job done. The right goal should be the synchronized, not the integrated supply chain. The tightly integrated supply chain is inflexible. Data integration at the transaction level is too simplistic. The data needs context, and there needs to be a middleware layer to enable the trade-offs of what-if analysis between source, make, and deliver. ERP is still important; but it is a piece of the puzzle, not the backbone.

3) What is the right customer response? Today, we are blind. As systems are currently designed, companies just do not know how to best serve the customer. There is a need to redesign Customer Relationship Management(CRM) to be more than just a Rolodex. Companies need insight on contract conditions for compliance, revenue management trade-offs to drive profitability, and cost-to-serve to improve the profitable demand response. Today, with existing technologies, companies react to orders. Orders do not reflect true demand. The further back a company is in the supply chain; the greater the gap.

4) How do I best match inventory with orders? Available to Promise (ATP) was a good first step, but it did not go far enough. Intelligence to align orders with inventory is lacking. It is a black hole. As companies become more complex through complexity from product portfolios, channels, or geographical footprint, the hole becomes more glaring.

5) Translation of Risk. The greatest risk in the day to day supply chain is demand. When the forecast is transmitted as a table of numbers versus the proabability of demand, we have trouble. Without visibility on the probability of demand and what-if scenarios to understand the impact of demand ranges, we cannot adequately plan.

The Road to Somewhere

The goal needs to be the synchronization of demand and supply signals with role-based predictive analytics that captures the trade-offs between make, source, deliver and selling decisions. If your architecture looks like the one on the left of figure 1, stabilize the ERP project and recognize it for what it is: a project to improve enterprise efficiency. It is not the path to the goal for the integrated end-to-end supply chain.

Instead, select system integrators that understand how to sense, shape and translate demand. Look for consultants that understand the new capabilities evolving in predictive analytics. Let’s face it, the major system integrators have made alot of money selling a false promise. It is time for the good times to end. We have some hard work to do, but our futures depend on it.

In the coming weeks, I will be writing more about the road to somewhere. My post this week will focus on driving the customer-centric response.

What do you think? How do we move from a focus on ERP backbones that are becoming increasingly expensive and inflexible to meet the requirements of the effective supply chain? Please send me your comments. Until then, the supply chain shaman will be coming the globe to find the best of new technologies to help your supply chain.