Functional silos define today’s supply chain organization. The silos compete. They lack alignment, and a result, cannot effectively collaborate. This lack of alignment is an impediment to improving balance sheet results.

I am a product of traditional, silo-based thinking. My first job was in manufacturing in the 1980’s. I did not understand warehousing and transportation until reassignment to a logistics role in 1985. I needed to experience it to understand it. When I cut my teeth on early forms of supply chain planning, I began to see the bigger picture. Sell, deliver, make and source need to fit together outside-in from the channel back. Like me, the traditional supply chain leader grew up believing in functional excellence and inside-out processes.

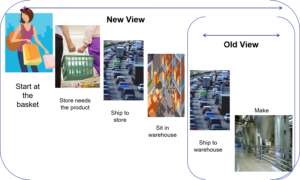

Inside-out processes assume that an order represents demand, and the supply chain’s role ends with a perfect shipment. Leaders know this is too limited a view while laggards still drive siloed functional excellence.

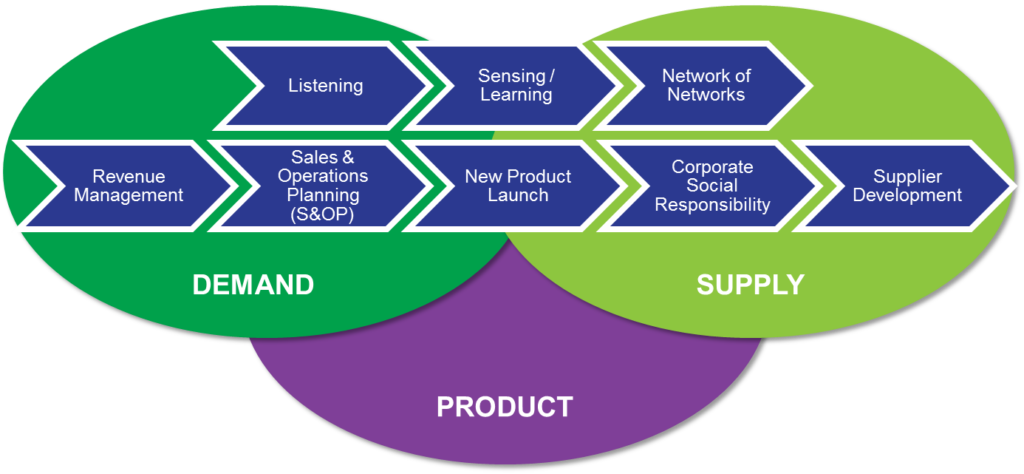

In the building of outside-in processes the leader acknowledges that an order is not the best representation of demand, and there is no substitute for market data (channel, distributor, and market drivers). In this process, slowly, as shown in the image of the consumer value network, supply chain leaders expand the scope of their supply chain operations from the customer’s customer to the supplier’s supplier, with a clear view on the customer. This is not an easy transition.

In the traditional supply chain world, the processes of sell, deliver, make, source, and plan are separate and distinct. The traditional metrics reward functional thinking. The SCOR framework embodies and epitomizes the traditional, silo-based thinking. This is also true of many of the organizations within supply chain. The focus of APICS is manufacturing, CSCMP’s foundation is in logistics, and ISM serves the procurement organization. Each organization is trying to refine the model for next-generational supply chain thinking, but they each have their own issues.

We must learn from the past to unlearn. The siloed organization is insular. It cannot sense, and is slow to adapt.

Alignment

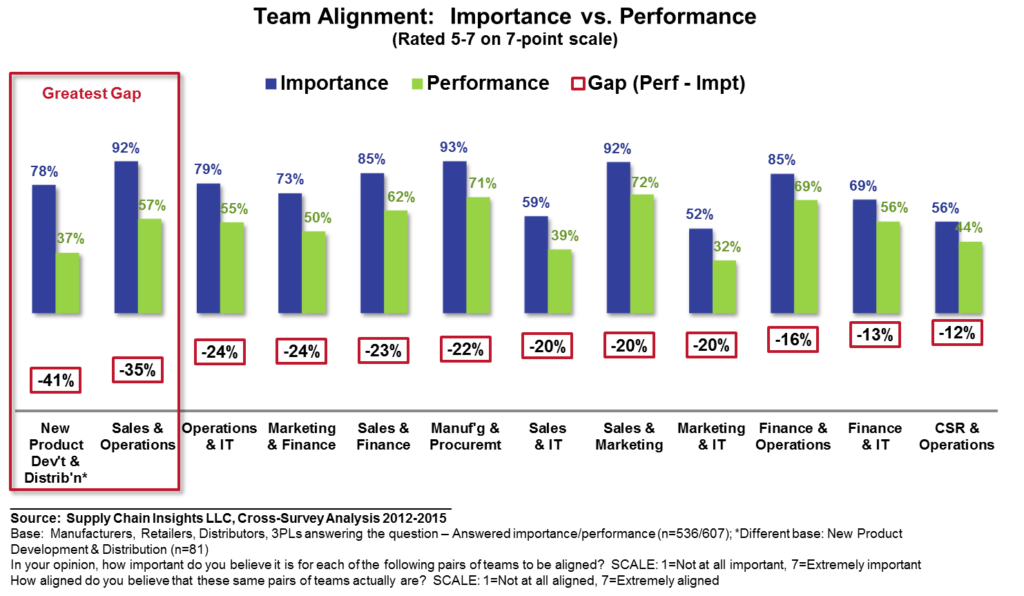

By definition, the silos struggle to align. Substantial gaps exist between the operations teams and finance, the operations teams and new product launch, and the operations teams and the sales/commercial teams. Closing these gaps is essential to driving a growth strategy. In our research we see that the successful implementation of horizontal processes helps to close these gaps.

The use of network design technologies along with simulation through a center of excellence can greatly improve the gap between finance and the supply chain organization. Similarly, revenue management augmented by cost-to-serve and aligned with S&OP can greatly improve the gaps between the commercial teams and operations.

Figure 1. Cross Functional Alignment.

State of Horizontal Processes

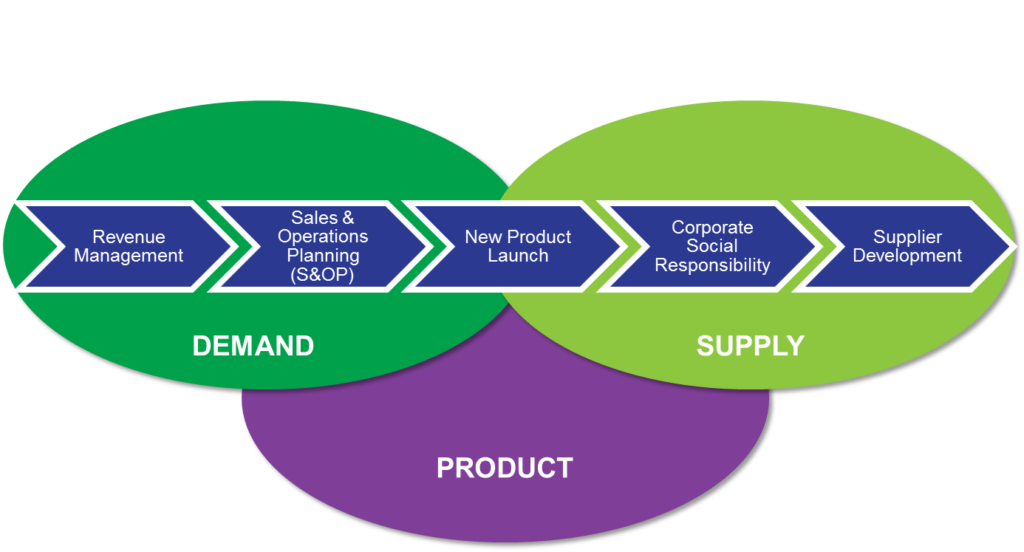

Horizontal processes within the supply chain organization help to align and orchestrate demand and supply to deliver on the business strategy. Effective design of horizontal processes reduces silo friction and improves organizational cross-functional alignment. It enables growth.

Figure 2. Definition of Horizontal Processes

While most supply chain teams think of these processes one-by-one–an example is improving S&OP in isolation of the larger system–it is a system. In our research we find that when companies outperform, one of the first things they talk about is success in horizontal processes. The second that they share is investment in network design. For reference, today, 52% of companies have a network design group, and 40% of these companies think they do it well.

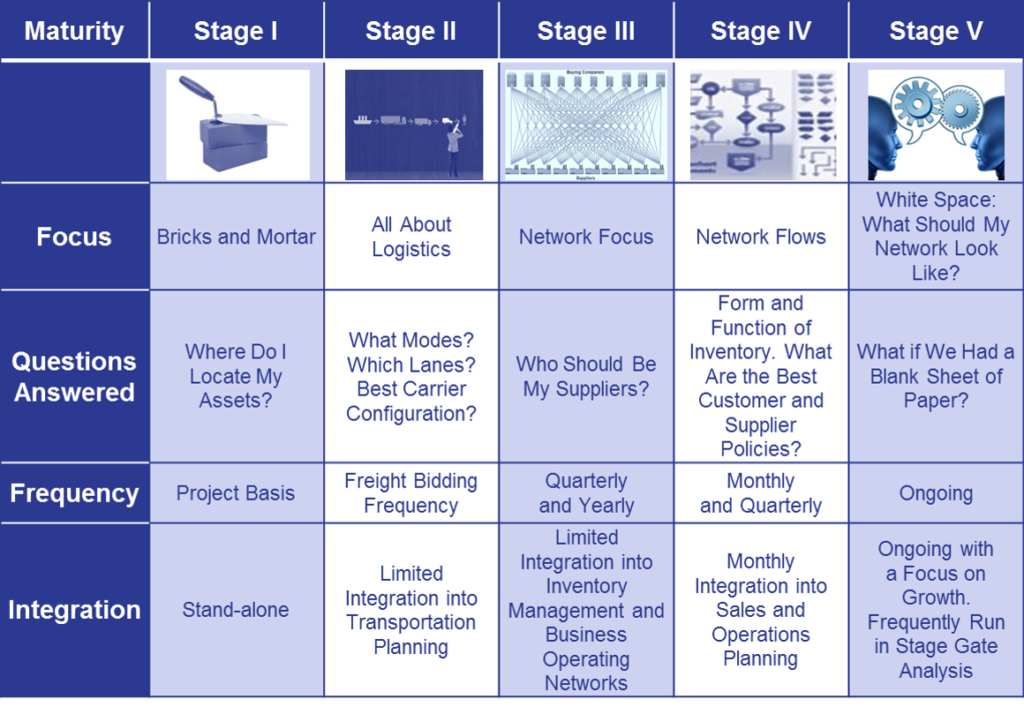

Underneath these horizontal processes is a strong network design plan. Not all companies are at the same level of maturity in network design. It means many different things to different people. In our research, the network design maturity model shown in Table 1 is helpful to many of our clients. Note in the maturity model that the most mature companies use network design technologies to inform and refine horizontal processes. This is less than 5%.

Table 1. Network Design Maturity Model

What do I mean from the outside-in? An outside-in process design starts at the market and uses channel data to sense and then shape demand opportunities while mitigating risks through cross-functional, horizontal processes. It is designed using optimization and simulation tools, and the network design processes are iterative on a monthly basis to improve the end-to-end set of horizontal processes. The most frequent processes I encounter in my work with supply chain leaders are revenue management, Sales and Operations Planning, New Product Launch, Corporate Social Responsibility, and Supplier Development. As shown in Table 2, each has a different level of adoption and satisfaction.

Table 2. Levels of Deployment and Satisfaction

Let me add a disclaimer. As you look at Table 2, please use some discretion. Each of these studies was completed using a different population at different times. The results are from different surveys each with a bias. (It is to be expected that the corporate social responsibility group would rate their processes more effective than the larger organization.) As a result, the data is relative, and cannot be compared in absolute numbers column by column. However, I think that the pattern is true. Supply chain leaders have stronger horizontal processes at the center of the supply chain than the ends. Very few companies have effective revenue management and supplier development programs. In addition, very few companies have designed these programs for new product launch. (The techniques for forecasting and planning new products is quite different.)

As we think about making the digital pivot, and implementing listening and test-and-learn programs to translate to the network of networks, we are entering into a new era. The thought of the supply chain as a growth engine is new to many. However, if companies listen, test and learn, and translate on top of strong conventional horizontal processes, I believe, based on the research, that great things can happen. Today I only know of nine companies that listen, and three that actively test and learn. But, I think that Figure 3 is an important element of making the digital pivot and defining next-generation supply chain. I think that this vision is the future.

Figure 3. Evolution of Horizontal Processes

What do you think? I look forward to hearing your thoughts.

Typing this quickly in the Atlanta airport as I run for a plane to Lima, Peru. I have been speaking at conferences around the world and inviting them all to watch the Supply Chain Insights Global Summit live-streaming where we will debate these concepts. We hope to see you as part of the debate!

How Do You Find Out More?

We are currently putting the finishing touches on the Supply Chain Insights Global Summit. (Registration is open for the first 125 participants. We limit the number of technology providers to 25% of the audience.) The conference will be live-streamed as we discuss five themes:

We are currently putting the finishing touches on the Supply Chain Insights Global Summit. (Registration is open for the first 125 participants. We limit the number of technology providers to 25% of the audience.) The conference will be live-streamed as we discuss five themes:

- Supply Chains to Admire. Financial Results. A critical look at supply chain processes impacting financial results through the Supply Chains to Admire research.

- Economic Vision of Supply Chain 2030. It is hard to know where we are going if we are not clear on the end state. Join us for a critical view of supply chain 2030 through the insights of leading economists.

- New Business Models. Making the Digital Pivot. Sit back and listen as companies share insights on the adoption of robotics, the Internet of Things, 3D printing, manless vehicles, new forms of analytics, and the emergence of new business models like Alibaba, Amazon, and Uber.

- Building Supply Chain Talent and Leadership. Insights on leadership, continuous improvement and talent development for emerging markets.

- Supply Chain 2030. Building Outside-In Processes. Experience the difference between traditional inside-out and new outside-in processes through the use of new forms of analytics.

About Lora:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is writing her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu(s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn.

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is writing her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu(s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn.

improvement and talent development for emerging markets.Supply Chain 2030. Building Outside-In Processes. Experience the difference between traditional inside-out and new outside-in processes through the use of new forms of analytics.