A plateau: a period of stability with no change

Last weekend, I wrote two reports. They published this past week. In the first report, I rolled up my sleeves and analyzed balance sheets of process companies over the past decade with Abby Mayer (@indexgirl). In the process, I discovered that the average process manufacturing company has reached a plateau in supply chain performance. Growth has stalled. To compensate and stimulate revenue, the companies increased SG&A margin by 1%. However, the conditions were more complex; the average company, over the last ten years, experienced a decline of 1% in operating margin, and an increase in the days of inventory of 5%. While cycle times have improved, the majority of the progress has come from lengthening of days of payables and squeezing suppliers.

As I wrote the report, I started thinking about all of the supply chain conferences that I have attended where supply chain leader after supply chain leader has stood before an audience and declared that they had reduced costs, improved inventory and improved customer service levels.

While I believe that individual projects may have had these results, it did not make its way to the balance sheet. I believe that we have reached a plateau and that supply chain performance is declining. One of the primary issues, shown in figure 1, is the executive team’s understanding of the supply chain. Over the past ten years complexity has increased, and many well-intentioned executives lack the understanding of the supply chain’s potential or how to manage the supply chain as a system.

A Need to Rethink Technologies?

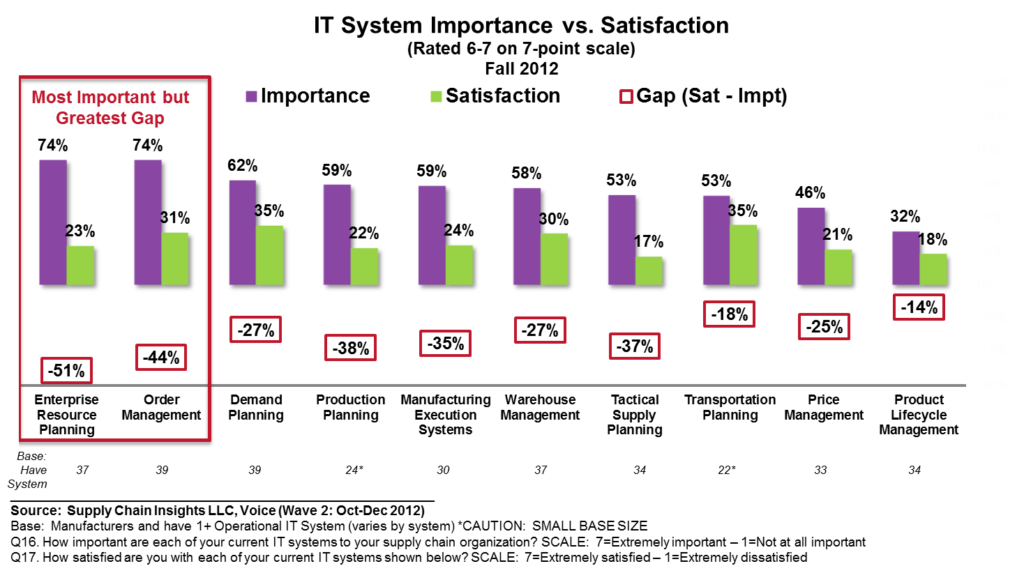

In the second report, I wrote about the current state of supply chain technologies. The greatest gaps are in the areas of the greatest importance. Companies are the happiest with supply chain execution systems, but the gaps in supply chain planning are high, and the ability to use the data from ERP and order management remains a gap.

The good news is that companies are increasing their spend on supply chain solutions. The bad news is that there are major gaps in the solutions where they want to invest. It reminds of the old Turkish proverb, “No matter how far you have gone on a wrong road, turn back.” I think that this is true. In my last post, The End of the Fairy Tale, I shared insights on the changing drivers within the supply chain and the need to rethink metrics and business goals. The fundamental design of supply chain systems has not changed since the mid-1990s despite the evolution of greater computing capabilities and the change in the business problem within the supply chain. The process requirements have changed in five fundamental ways that are not reflected in the software:

-

The move from vertical to horizontal processes. There is a need for automation and new forms of predictive analytics to power horizontal processes. The need to automate revenue management, social responsibility, supplier development and Sales and Operations Planning (S&OP).

-

A need for new forms of analytics to sense using structured and unstructured data. Today’s supply chains respond. They do not sense. As a result, the response is usually late. There is a need to use unstructured text data mining technologies to listen and learn.

-

Inter-enterprise solutions using cloud-based computing. The supply chain is slowly adopting new forms of cloud-based computing to align and synchronize.

-

Movement from Inside-out to Outside-in. The traditional supply chain planning systems primarily use orders and shipment data for planning. There is a need to redesign the technologies to use channel data market-to-market to sense, shape and drive a more flexible response.

-

Visualization and better use of data. The traditional definition of supply chain planning was data intensive and insight poor. There is an opportunity to build a new generation of applications using new forms of mapping and visualization to drive new insights.

Today, we have the evolution, not the reinvention, of current systems. Vendors are consolidating and innovation is largely absent. The other day, I was reading about IBM in 1964, and the introduction of the IBM 360. The IBM 360 was a tough decision for Thomas Watson because it made the prior computers obsolete. The APS market needs this type of leadership. I think that there is a discontinuity and we need to declare the APS and ERP systems of the 1990s obsolete and start again. I think that they are legacy. What do you think?