Today, data moves fast, but supply chain decisions move slowly. I know a bit of a generalization, but ironic, right? The reasons are many, including data latency (the time to clean, load, and use data), process latency (the time for an organization to decide on action after getting the data), demand latency (the time from channel consumption to order visibility), market latency (the time from a market shift to the translation to customer order) or transparent governance (a defined process on how an organization should make a decision).

In work on outside-in processes, we established that the current demand cycles are:

Unfortunately, companies focus on supply cycles lacking an understanding of demand.

As variability increases, more and more companies would like to use market data from the channel or the supply base, but the design of current systems is an obstacle. The reason? Current technologies based on relational database architectures require pristine transactional data, and market data is disparate–available in many forms, including streaming and unstructured data, event and weather profiles, images, and pictures. The data lacks synchronization and usability.

The Quest to Use Real-Time Data

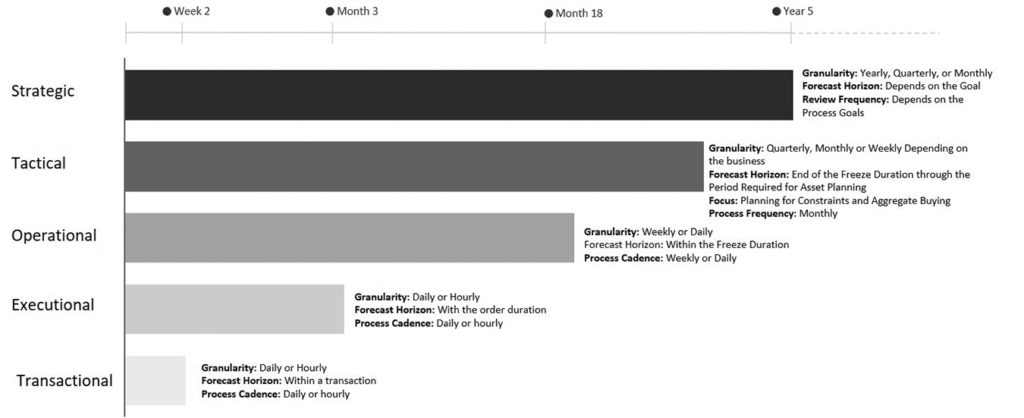

Real-time data surrounds the supply chain, often as streaming data. For this article, we will define real-time data as the availability of data and the usage within 15 minutes of the occurrence (writing or publishing from an input system). In contrast, we will define data available at the speed of business and data usage with minimal process latency within planning horizons. Each planning horizon shown in Figure 1, operates at a different cadence. Over the past thirty-three months of disruption, companies became more reactive, shortening the focus of planning to operational and executional time horizons.

Each planning horizon serves a purpose. Planning outside of lead time in the tactical horizon is essential to manage costs, defining buffers, and sourcing strategies. Operational, tactical, and strategic processes should never be real-time. The reason? Real-time analysis of market inputs introduces noise into the system amplifying the bullwhip impact and creating alignment issues for employees to align on executing a decision.

Figure 1. Definition of Time Horizons

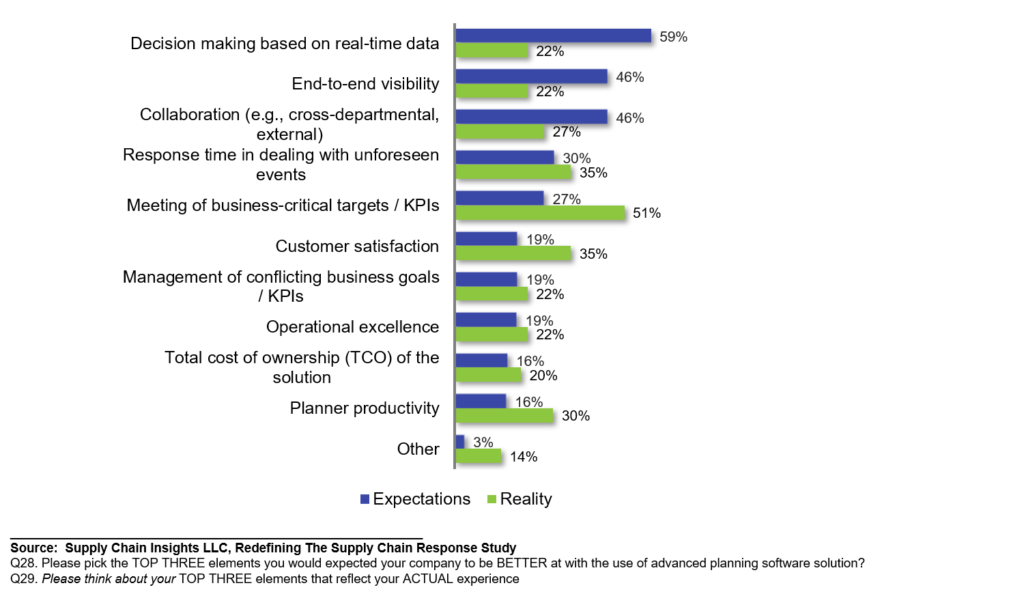

While as shown in Figure 2, we offer recent research results. Note that 59% of companies surveyed seek real-time planning and experience a gap in expectations. In contrast, the real value of planning is meeting business-critical targets/KPIs. Planning helps organizations to understand the complexity of functional trade-offs, which are not apparent without modeling. I define these trade-offs at the Effective Frontier. (In economic theory, we termed this the Efficient Frontier, but I avoid using the term Efficient Frontier because of its use in supply chain management as the design of the lowest cost supply chain. The efficient supply chain or the supply chain that operates at the lowest cost is usually only the best design for 20-25% of items. Efficient flow is only one type of design.)

Figure 2. Goals of Planning Measured Against Benefits Gained

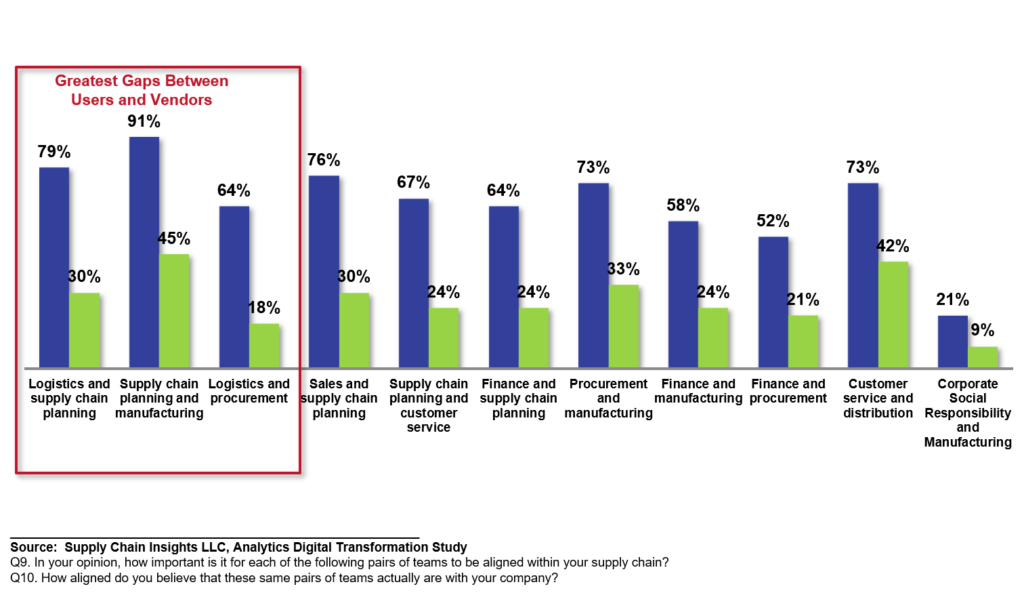

The gaps in expectations between planning and functional organizations like manufacturing, transportation, and procurement are large and growing. The reasons are many. Many planning systems were viewed as technology implementations, and companies never tested the validity of plan outputs. Others implemented as a large architecture are difficult to use. Only 33% of companies have what-if capability. As shown in Figure 3, planning is not serving any function well. But is the answer real-time planning? I think not. Instead, I believe it is the alignment of planning processes to operate at the speed of business, recognizing the cadence and defining the governance of each planning horizon.

Figure 3. Organizational Alignment

The So What?

So the next time that someone in a meeting asks for real-time planning stop the discussion and get clear on definitions. Questions to ask:

- What does real-time mean?

- How will real-time data improve outcomes?

- What is the right cadence of doing business? How can process and data latency align with these rhythms and cycles?

The five areas of opportunity for me in the use of real-time data are:

- Use NoSQL and Unified Data Models to pull warehouse data on a real-time basis to improve the perpetual inventory signal and drive cycle reduction in ATP for order promising. (However, this requires the redefinition of Available to Promise (most existing engines cannot operate at the necessary speed and accuracy.)

- The use of AIS, GPS, and Trucking Telematics to improve deployment and routing in transportation. (Again, this requires the redefinition of current transportation engines. You cannot just stuff a telematics signal into existing transportation deployment solutions and get a better answer.)

- Shifts in manufacturing scheduling and cross-docking based on inbound logistics signals to improve the synchronization of tight supply.

- Improvement of second pass tender offers in broker markets in volatile transportation markets. (However, the first work needs to focus on improving the acceptance of the first-pass tender.)

- The mining of unstructured data in customer service call centers to understand quality and warranty issues at the speed of business as a listening post.

These are my thoughts. I welcome yours. My goal is to improve decision-making at the speed of business and improve supply chain planner satisfaction and work-life balance. I find that we are having too many of the wrong discussions.