Dear Supply Chain Leader,

Today, sitting in my seat in 11K on a Cathay Pacific flight between Hong Kong and Boston, I want to report that there is no Easter Bunny. There is also no Santa Claus. Yes, our parents perpetuated the image of that elderly white-haired gentleman, a symbol of Christmas love. This bunny in the basket is not real. Sorry to break the news.

Today, sitting in my seat in 11K on a Cathay Pacific flight between Hong Kong and Boston, I want to report that there is no Easter Bunny. There is also no Santa Claus. Yes, our parents perpetuated the image of that elderly white-haired gentleman, a symbol of Christmas love. This bunny in the basket is not real. Sorry to break the news.

In Galileo’s world there was a belief that the world was flat. We now know, based on years scientific discovery, that the world is round. Today, sitting in my airline seat, I can track the plane’s progress on my screen as we cross-over the North Pole. No doubt in my mind, the world is clearly round.

Today, I also want to report, that based on over a decade of scientific discovery that traditional supply chain practices are not best practices. They are evolving and maturing, but we are not there yet. Why do I believe this?

Let me explain. The evolution of supply chain processes is now fifteen years old. Process maturity is greater for supply chain execution than supply chain planning. As supply chains became more global, the original regional definitions were insufficient. Stuck at the intersection of operating margin and inventory turns; today, only 10% of companies are making progress. Politics and alignment issues abound. In the face of growth strategies and increasing complexity of product portfolios, the efficient supply chain is not effective. The supply chain needs to be more agile and responsive.

Corporate boards and shareholder activists want more. As a result, many companies are struggling. Intuitively leaders feel there is a better way. The news is full of vendor names who they do not know. Leadership teams are uncomfortable. Analytical innovation and digital transformation drove step-change capabilities within the office and marketing. The question is, “How can the supply chain leader drive digital transformation to deliver transformational capabilities?”

Five Barriers to Driving a Digital, Outside-in Transformation

The first step to drive a digital transformation requires companies to acknowledge that traditional supply chain processes must go. They are obsolete, historic, and traditional. They are not best practices. Rewire the supply chain from the customer’s customer to the supplier’s supplier. It is not an evolution. Adoption of digital supply chain practices requires rethinking the basics, and admitting that today’s practices are out of step with the market. It is hard because academic programs are out of step with the market, and that the consortia programs of CSCMP and APICS, while driving functional improvements, are not equal to the task of giving us the building blocks to drive a digital transformation. The SCOR model defines functional improvements, but falls short in defining cross-functional supply chain transformation. Let’s start by addressing the barriers.

Barrier #1. Inside-out Thinking. The traditional supply chain is inside-out, triggering processes on the back of order-to-cash and procure-to-pay financial processes. It is not sufficient. The digital transformation requires the building of outside-in supply chain capabilities to sense shifts market-to-market, from the customer’s customer to the supplier’s supplier. In this transformation the supply chain is not a function; instead, it becomes a transformative capability that is the fabric of an organizational transformation. It is about the effective use of channel and market data, the transformation of cross-functional capabilities, and building effective value networks. The mission for most companies is to drive transformative growth strategies.

Barrier #2. Momentum to Invest in Traditional Technologies. Designed to make the traditional supply chain more efficient, today’s IT investments struggle to balance demand and supply, and drive profitability. The CIO budget is hamstrung with system upgrades and software license payments. Funds are hard to obtain. Most companies are busy doing traditional projects. Resources working hard on multi-year ERP transformations have little time to discuss a digital transformation. Resources are a constraint. It is also hard for the organization to admit that the investments in traditional APS and ERP are largely legacy. (While ERP and APS are still used in the digital transformation, they are not the backbone of tomorrow’s supply chain.)

In the digital transformation these traditional applications manage low-velocity transactional data. High-velocity or streaming data requires different architectures built on non-relational, cloud-based architectures using open source tools like Apache Spark. There is the need for an analytics strategy that can power outside-in, real-time processes using structured AND unstructured data. Supply chain leaders need to find funds to invest in technologies that are new to IT organizations. There are many opportunities. The issue is where to start. Is it the use of sentiment data in combination with demand sensing pattern recognition to redefine demand? Or to move from predictive analytics to prescriptive/cognitive capabilities to sense/learn and act? Or to move from portals/dashboards to using canonical many-to-many data models in value networks for the extended supply chain? Or is it the use of the Internet of Things to transform manufacturing or reduce issues with counterfeiting? The opportunities are numerous.

This challenge to the status quo is uncomfortable. The IT organization has strong competencies in relational applications with three-letter acronyms (APS, ERP, CRM and SRM). CRM and SRM are not the enterprise adapters to build value networks. Many teams will fight to gain recognition that anything which is not labeled SAP or Oracle will be good for the supply chain. The answer is to start small. Fund a scrappy cross-functional team to learn about new forms of analytics and build outside-in pilots in business units with forward-looking thinking. My challenge to you is to define the analytics space that lies between operational systems and workforce productivity technologies. (It is labeled green for a reason.)

Barrier #3. Sensing. Today’s supply chains respond. They do not sense. Market data pools at the steps of the supply chain organization, yet it is not used. Companies struggle how to use market, customer sentiment, and channel data. Stuck with inputs from the traditional processes of collaborative forecasting, and traditional definitions of demand planning, demand error and bias are high. First- and second-generation supply chain applications defined demand management based on order and shipment data. In the face of today’s volatile markets, due to increasing demand latency, demand planning based on order and shipment history is insufficient. These traditional forecasting processes perpetuate the Bullwhip Effect, amplifying and distorting channel pulls. The reason? The process is flawed. Traditional demand planning uses great statistical modeling to predict the future using order patterns. This issue is that the orders have inherent order latency (The time for customer purchases to translate to manufacturing orders). Orders do not represent market demand. As the long tail of the supply chain grows (products with lower demand and lumpier patterns), the greater the need for change. Why? The signal is out of step with the current market. The longer the tail, the greater the issue.

Barrier #4: Batch Processes. Due to the limitations of computer processing in the 1990’s, batch IT defined supply chain processes. Today, with cloud-based in-memory processing and the Internet of Things, we should not have to wait for insights from data. Break down the walls and challenge traditional batch processes. Try to define IT processes that move with the cadence of markets. Today’s supply chain processes are out of step. The supply chain is reacting on late data with a low level of insights. If this is you, don’t accept the status quo.

Barrier #5: The Efficient Supply Chain. There is a belief that the efficient response—the tightly integrated lean supply chain—defines supply chain excellence. However, in today’s organization, the efficient supply chain is probably not the most effective. In most organizations product and channel complexity is increasing. This complexity requires increased agility. The dilemma? A supply chain cannot be efficient, responsive, and agile simultaneously. It is about conscious choice. The longer the tail, the greater the need for an agile or responsive supply chain. To continue the discussion, let’s stop and define some terms:

- Efficient Supply Chain. This is the supply chain delivering the lowest cost per unit. This is the world view of finance and why there is so much friction between procurement and finance. To move forward, and gain consensus, requires the education of the finance team on demand-driven and market-driven concepts.

- Responsive Supply Chain. Short cycles define the responsive supply chain. Short cycles require buffer inventories and short lead times. It is the design for companies with large demand pulls and unpredictable demand. This is the world of vaccines, allergen drugs, promotions, bathing suits, and fast-fashion.

- Agile Supply Chain. The agile supply chain is volatile. The goal of the agile supply chain is to deliver the same cost, quality and customer service given the level of demand and supply volatility. It requires ongoing design modeling to ensure that buffers and lead times optimize the response. It is also dependent on supplier development and the support of value chain relationships.

Recommendations

Here are five recommendations to get you started:

- Start Small. Build a scrappy, cross-functional team to test and learn using new forms of analytics. Give this team a mission. Don’t let them drift. Build the charter of this cross-functional team with the goal in mind. Give the team something that is mission critical, and then market the impact of their contributions.

- Self-fund and Operate the Initiative in the Line-of-Business. Self-fund the team’s efforts by taking a portion of the funds that you are saving in continuous improvement programs.

- Align Cross-functionally Against a Burning Platform. Is the goal to become more customer-centric and drive growth? Build e-commerce capabilities? Drive better performance in new product launch? Seize the opportunity.

- Challenge the Status Quo. The most advanced case studies of success in analytics platforms are in the financial, insurance and services industries. Learn and adapt the thinking to your industry.

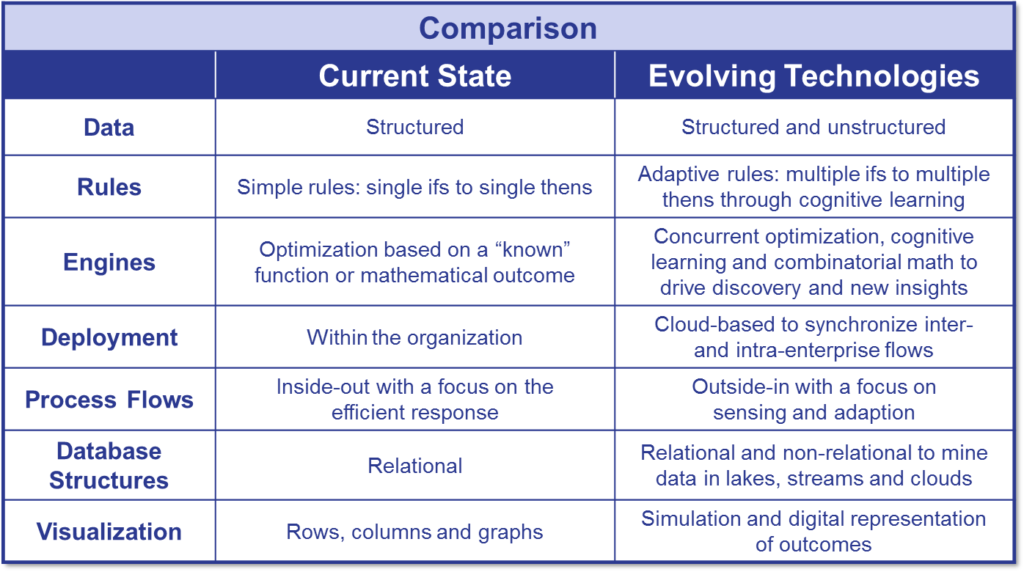

- Build the Mission by Looking at Pattern’s in Last Year’s Performance. Chart the course of the team by hosting a workshop where you review the past year and brainstorm/outline the problems the team encountered. Maybe it was a failed new product launch? An issue with supplier reliability on fair labor? Large-scale product write-offs or a quality problem? List them and then ask yourself, “What data did I have in the organization? How could I see it and respond faster?” Plot the data and then challenge yourself to think about new forms of analytics that can help. Use Table 1 as a guide.

Table 1. Bridging the Current State of Technologies with Evolving Analytics

In the process let’s remind ourselves of some cold hard facts. Since 2000, 52% of the companies in the Fortune 500 have either gone bankrupt, been acquired, ceased to exist, or dropped out of the Fortune 500. Today shareholder activist campaigns against companies with a market cap greater than $10 billion has more than doubled since 2010. Activists won, partially won, or settled 73% of proxy fights in 2014; this is up from 55% in 2010. Challenging the status quo is essential. (source Moody’s)

Challenging the Status Quo

In closing let me shift gears and tell a story. Sitting in seat 32D in economy on my way back from Europe in November, I struggled with the sardine effect. If you are a traveler I am sure that you can relate. (There was so little room that I contorted my body to the angle of the seat in front of me.) Bored and frustrated I resorted to mindless movie watching. The broken monitor gave me few options. The only movie available was “That Sugar Film.” I was not interested; but I sighed, and punched it anyway on my screen. At that point I needed something to relieve the boredom. Surprisingly, the movie was transformational for me. As a gal that loves to cook and eat I have always fought weight. For many years I have counted calories, and laughed as I watched fad diets come and go believing that a calorie is a calorie. The point of the movie is that a calorie is not a calorie. The plot is simple. A healthy young man uses his body to test the impact of sugar. He hires a team of doctors and mental health professionals to track the shifts in his body as he changes his diet to a low-fat diet based on commercially available foods. (The sad fact is that many of the items labeled “low fat” are high in sugar. When there is a switch to low-fat eating many people unknowingly increase the levels of sugar in their diet.) Eating the same level of a caloric diet and exercising at the same level, the main character in the movie gains 8 kilos in less than six months.

Let me confess: I crave sugar. I am not a carbonated soda drinker, but I love a good dessert with coffee. I am also a huge fan of Reese’s seasonal peanut butter chocolate treats. (BTW, Jason Reiman, I was very disappointed in this year’s skinnier Reese’s Christmas trees. I preferred your fat trees. I love the peanut butter/sugar combination.) Sorry to digress. I rationalize my behavior as rewarding myself with a few perks in my road travel. For those of you that belong to the million-miler clubs I am sure that you relate.

On the trip back from Europe, stuck in the middle seat in the back of the economy section with almost no leg room and the seat in front of me in my face, I watched the movie twice. At the end of this trip I vowed to swear off sugar. It has been five weeks. I must admit it is very hard. My only sugar now is fresh fruit. My body is slowly changing. I am tracking weight, inches, and blood glucose levels quarterly.

Why do I share this story? For years healthcare professionals perpetuated the belief that a calorie was a calorie; and that calories in the diet from fat were bad. (Yes, I know from my years in dietetics that a gram of fat has 9 calories while a gram of protein or carbohydrate has 4 calories. And yes, I was fully schooled in the need for micronutrients and vitamins, but I underestimated the impact of refined sugar on the body.) In the United States, the FDA, buoyed by sugar lobbyists, built educational materials that a calorie was a calorie. In parallel, the culture shifted to commercially prepared low-fat meals high in sugar. I had no idea how many tablespoons of sugar I was unconsciously consuming. Shocked when figured it out, I changed what I eat.

Today I believe that a calorie is not a calorie. I know that the Easter Bunny and Santa Claus were gifts of love from my parents. They do not exist. I can also see from the moving screen on my monitor on this long flight as I cross over Antarctica that the world is round. I also hope that I have convinced you that traditional supply chain practices are not best practices. Instead, I firmly believe that we need to test and learn, and evolve practices outside-in, based on new forms of analytics. I believe when we do seize this opportunity we fuel the Fourth Industrial Revolution.

Next Steps?

Question the status quo. Learn continuously. Don’t know where to start? Join us. If you want to know more, join our networking sessions. Gain insights and learn from our webinars. The first opportunity to learn is attending our Shaman’s Circle Networking event at Amelia Island, Fl on April 17-19. The event is by invitation only for Supply Chain leaders. The gathering is small networking event and the cost is $1500 for two days. Let me know your interest.

I would also encourage you to pre-register for our Supply Chain Insights Global Summit in Scottsdale, AZ on September 8-9. The cost of the event is $1750. The overarching theme is to Imagine Supply Chain 2030. In the creation of the program I handpick the speakers against five themes:

I would also encourage you to pre-register for our Supply Chain Insights Global Summit in Scottsdale, AZ on September 8-9. The cost of the event is $1750. The overarching theme is to Imagine Supply Chain 2030. In the creation of the program I handpick the speakers against five themes:

- Shifts in the Global Economy: What will the world look like in 2030 and how does this impact the global supply chain?

- Celebration of the Supply Chains to Admire Winners. Now in its third year, we will continue to celebrate the journey of companies that are making more progress than their peer group in performance and improvement in operating margin, inventory turns and Return on Invested Capital (ROIC). Look for this report in July this year. At the conference we will hear from three or four Supply Chains to Admire winners.

- Making the Digital Pivot. I am sorting through case studies of the Internet of Things, manless vehicles, 3D printing, advanced analytics, and robotics. This section will be a rich sharing of case studies.

- Leadership and Driving Continuous Improvement. Case studies of companies driving progress and pushing the status quo.

- Outside-in. The value proposition of outside-in processes.

True confession. I did not want to start a new analyst company, but we do it because we think that there is a need for independent, forward-looking research to help the supply chain leader. If this speaks to you, join us in defining the digital, outside-in value network of the future. Let us help you tell your organization that there is no Santa Claus. No Easter Bunny and no Supply Chain Best Practices.

About Lora:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for supply chain excellence.

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for supply chain excellence.