Remember the Jetsons? While the Flintstones chronicled a Stone Age family with work powered by birds and dinosaurs, the Jetsons symbolized the future. The show aired with catchy music from 1962 to 1963, then later in syndication, with new episodes, in 1985 to 1987. While the Flintstones rolled around in crude vehicles with stone wheels, the Jetsons rode high over the city buildings in airborne spacecraft. Robots and automation enriched the Jetsons’ lives.

Remember the Jetsons? While the Flintstones chronicled a Stone Age family with work powered by birds and dinosaurs, the Jetsons symbolized the future. The show aired with catchy music from 1962 to 1963, then later in syndication, with new episodes, in 1985 to 1987. While the Flintstones rolled around in crude vehicles with stone wheels, the Jetsons rode high over the city buildings in airborne spacecraft. Robots and automation enriched the Jetsons’ lives.

Last week I was having breakfast with the CEO of a leading software supply chain management company. When I was an analyst in 2001, I loved speaking to him. At that time he aggressively pursued automation, and actively tested new technologies. Two decades later he is more conservative. As we buttered our toast he teased me. “Lora, you write about cognitive computing often stating that it will usher in the Third Act of Supply Chain Planning. I don’t get it. Isn’t this like the Jetsons? I am struggling with the concept. Is it real? How will it be used? Help me with the use cases.”

I laughed and said, “Oh my! Yes. Today’s supply chain is like the Flintstone era. Planners work hard for many hours and get very little done. We have tried to automate a nonlinear system with linear optimization. It is like a square peg in a round hole. There is a limited vision of what planning could be. In the 1990’s we designed traditional processes. Constrained by memory, we argued about 32-bit architectures. Today we are not constrained by memory.” He smiled and nodded. I then picked up a napkin and started drawing. (The best discussions happen on a napkin.)

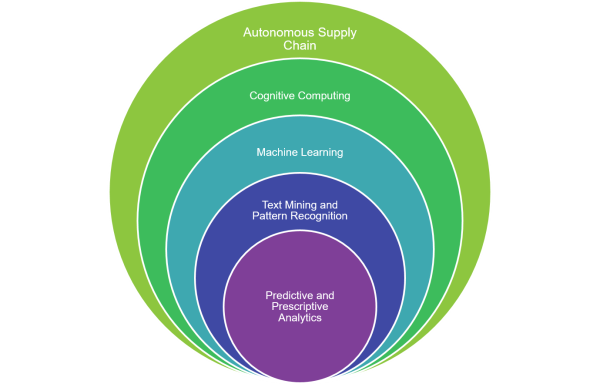

Figure 1. Relationships Between Concepts

The first discussion was on the progression of analytics. I drew the concentric circle drawing shared here. The CEO’s solution is predictive analytics. We discussed the evolution of pattern recognition software and prescriptive analytics. (This includes solutions like AIMMS, Opalytics, SAVI, and Terra Technology.) In each example, we discussed how the engines worked and the problems solved. We then discussed the evolution of machine learning. The example I used was the RuleX/ToolsGroup partnership and the evolution of the self-correcting supply chain. (The reading of data patterns feeding the planning engines and self-adjusting based on machine learning.) We then discussed the evolution of cognitive analytics: the extension of machine learning based on semantic reasoning. The examples are IBM/Watson, Enterra Solutions and FusionOps. With each circle, the supply chain gets closer and closer to being an autonomous supply chain.

The napkin was full of scribbles. Here is a synopsis of the use cases discussed:

- Data Mapping. The average company has 5 to 7 Enterprise Resource Planning Solutions (ERP). While the solutions are sourced from the same provider, each has a different data definition. It is difficult to map data from one to the other. The use of cognitive learning with a rules-based ontology enables the mapping of data with different context.

- Automation of Master Data Management and the Replacement of Data Standards. Today master data is hard-coded. The data definitions are manually determined and mapped. They are inflexible. As the business changes, the data becomes obsolete. With cognitive learning we redefine master data. It is adaptive.

- Redefinition of Rules. In the first generation of planning technologies the rules were single “ifs” to single “thens.” Rule sets –like ATP, VMI, Transportation Routing, Allocation and Assortment logic– are simple rule sets. Too simple to meet the business need. The problem is that they are not robust enough. An order is not an order. A customer is not a customer. An item is not an item. Each status needs mapping based on business rules. Cognitive learning will redefine rule the supply chain. Today’s supply chain does not play by the rules; however, we try to constrain and limit the options through rule definition that limits the possibilities.

- Rethinking Demand Management. Today companies try to get very precise on imprecise data. Rows and columns define forecasting. Companies lose visibility on the patterns and demand flows. Cognitive learning solutions provide systems of insights that can combine profile pattern recognition along with learning on unstructured data. Examples include the number of google searches on an illness or symptoms, which is a predictor of the spread of an illness and subsequent prescription sales. Social sentiment on twitter and Facebook combined with point-of-sale data drives insights to understand regional sales in days. Today it takes weeks.

- Planning Master Data. I only know a handful of companies that have a planning master data layer feeding their supply chain planning engines. Most companies install supply chain planning solutions, stabilize the implementation, and then forget about them. The data parameters of lead times, cycle times, and rates quickly become outdated. In most cases this data is a variable not a constant. For example, moving rail through Chicago in the winter is not the same as the summer. Unloading a container in Long Beach varies by the season; yet, the planning systems have a fixed value.

- Rethinking Decision Support. Building Systems of Insights Cognitive computing, layered on existing decision support tools—revenue management, trade promotion management, demand planning, production planning, transportation planning and supply network planning–drives deeper insights. The goal is to stabilize the current solutions and layer cognitive solutions on top of more traditional solutions like Logility, JDA, and SAP APO.

- Listening Posts. Today’s analytics drive answers on the questions we know, but we cannot track the important data that answers the questions which we do not know. Examples are many. Why are consumers raising concerns on quality? What do patterns tell us?

- Quality. Many production environments–coolers, dryers and distillation columns–are complex with many variables. Once the variables exceed 5 to 7 it is hard to model outcomes without collinearity. Cognitive learning enables new forms of insights to better control quality.

- Customer-Centric Supply Chains. Cognitive learning is ideal to map customer policies to fulfillment. The dynamic nature of inventory to order matching is difficult. This is an area of great opportunity.

- Network of Networks. The connection of data between trading partners is a use case that excites me. In this podcast episode, I explain some of the planned tests. For more on this important initiative join our webinar on January 11, 2017. We will be testing the potential to replace EDI messaging through the combination of Apache Spark, Blockchain and cognitive learning. In short, today’s business networks lack agility and are too costly. We believe that cognitive learning improves data mapping and gives insights to data relationships and inferences which are not obvious.

I hope this helps. We need to move from the Flintstone era. We are still not in the era of the Jetsons, but cognitive learning’s potential to drive value is exciting. As the ball drops in Times Square on January 1, 2017 it ushers in the era of cognitive learning.

If you speak to a provider of cognitive learning, realize that there are many options. Most know data, but do not know supply chain processes. Spend time ideating and realize it doesn’t happen overnight. Within five years we will have a redefinition of supply chain planning. Supply chains will learn as we sleep, and the insights will be deeper and richer with fewer people. It is coming. It is real. Are you ready? In this blog I will be providing case studies, technology overviews, and training to help. It is my goal to help supply chain leaders globally through independent and open research.