In the design of planning systems, it is important to think through the elements. These include data inputs, data model fit, engines, outputs, visualization, ease of use, workflow/what-if analysis, master data, and integration. The least problematic element is integration. However, and ironically, integration fears drove many decisions in the past decade.

A Closer Look at Forecasting

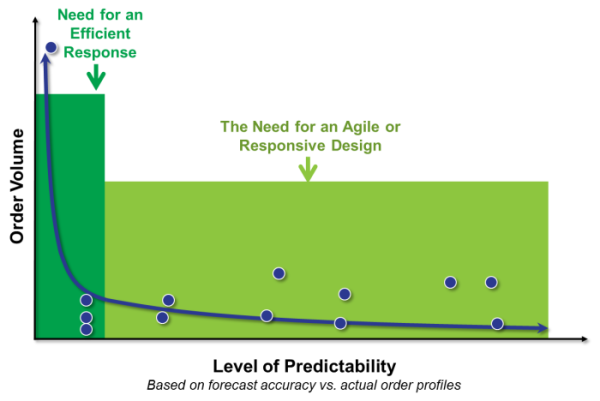

Traditionally, companies forecast using history (shipments or orders) as inputs and apply linear regression to understand the patterns of historical demand. The output is a time-series format. This methodology does not work well for Long Tail items or spare parts. What do we mean? In Figure 1, we depict the long tail. When items are on the long tail of the supply chain, demand is lumpy and unpredictable. As a result, traditional forecasting methods do not work very well to predict future forecasts. Here, through a case study, we explain the concepts of probabilistic forecasting (a type of math or an alternative engine) to predict lumpy demand.

Figure 1. The Long Tail of the Supply Chain

Spairliners: A Case Study in Probabilistic Forecasting

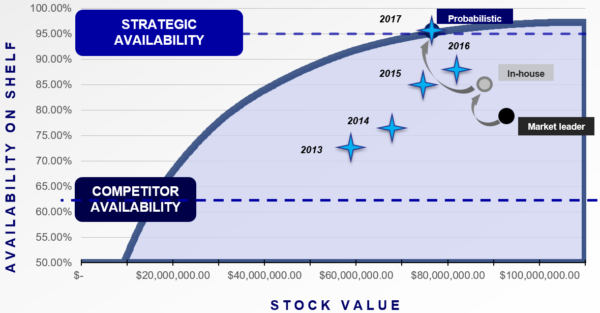

For many years, Spairliners, a provider of airplane spare parts, attempted to use traditional techniques to model requirements, but failed. In order to provide the extremely high level of service demanded by their customers for unpredictable spare parts requirements, the team tested alternative modeling techniques. Probabilistic forecasting drove the best results, as shown in Figure 2.

Figure 2. Improving Value Through the Testing of Forecasting Techniques

About Spairliners

Spairliners, was founded in 2005 to provide spare parts for Airbus A380 planes (the largest passenger airliner in the world). Customers include Qantas, Air France, Lufthansa, and Malaysia Airlines. Spairliners guarantees component availability.

The cost of an airplane on the ground in terms of lost business is extremely high for an airline due the high asset costs. Therefore, the availability of spare parts is critical to revenue for these airlines. Predicting spare part requirements is extremely difficult, as past demand is not indicative of future requirements. To meet the need, the Spairliners planning team knew they needed help in inventory planning. Their challenge? To provide one billion yearly components flying hours, manage over $200M in inventory, and guarantee with a 95-99% target for on-time delivery for their customers. As shown in the Figure 2, in 2013 Spairliners had 73% stock availability, and by 2017 their stock availability increased to 95%. They accomplished this through probabilistic forecasting.

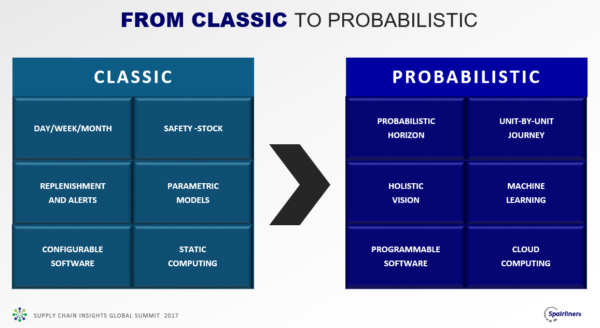

Understanding Probabilistic Forecasting

Probabilistic forecasting in supply chain is relatively new. and assumes that there is not a single future. It is the case of many possible futures. It is a best fit in a business process when demand data does not follow a normal distribution. Traditional approaches assume a fixed outcome and that the data is equally distributed around the mean. This is not the case for long-tail items, new product launch, and spare parts planning. In probabilistic forecasting, the output is not one number. Instead, it is a listing of probabilities for all future demand. A sample output is shown in Figure 3.

Figure 3. Future Demand Is Not Certain

The probabilistic model output accounts for both lead time and demand  forecast probabilities. The cost of stock, and the cost of stock-outs, guides the numerical optimizer to balance inventory recommendations.

forecast probabilities. The cost of stock, and the cost of stock-outs, guides the numerical optimizer to balance inventory recommendations.

At the Supply Chain Insights Global Summit, Spairliners’ Material Planning Manager, Antony Nardozza (pictured), noted the importance of change management to the successful implementation of probabilistic forecasting projects. (Reference the video.) When pressed on the adoption of a complicated model to the supply chain, he stated the team did not have to understand the math. Instead, outcomes need to be the focus. To prove the validity, the team uses historical information to test predictions.

The biggest challenge? Change management. The mindset of employees is quite fixed on the paradigm of traditional forecasting process definitions. The goal is to have employees start thinking in terms of the probability of future demand. Where previously, employees based the future on the past, instead, the probability of future demand units determines the outcome. Then based on this probability, the number of units needed in stock at all times was no longer a forecast plus a safety stock, but was instead a quantity based on the desired service level and the probability of future demand. This seems like semantics, but there is only one inventory number determined based on the desired service level instead of a safety stock inventory and a forecast inventory.

Figure 4. Managing Change in the Implementation of Probabilistic Forecasting

The change in thinking doesn’t stop at safety stock quantity, as seen in Figure 4. In the case of probabilistic forecasting, the probability of future demand and the probability of lead times drive inventory levels.

Recommendations

- Align Demand Planning Engines to Product/Demand Profiles. For long-tail products with a lumpy forecast—spare parts, new product launch, kits—consider probabilistic forecasting.

- Test and Align Forecasting Engines. Employees tend not to trust system recommendations without fully understanding the logic behind the math. Test the software, and take the necessary time to ensure employee satisfaction based on the outputs, and make changes to inputs if needed based on feedback. This will save time in the future, and will increase trust in the system, leading to less manual overrides.

- Don’t Underestimate Change Management when Implementing Probabilistic Software. No matter how good the software output is, unless employees embrace the new way of doing things, many times the benefits are not realized. Drive engagement. Test and learn and prove the output.

Conclusion

For difficult demand profiles, probabilistic forecasting is a new and powerful technique. It is a type of engine. Forecasting is all about better math, and the fit of the data model to drive outcomes. This implementation was extremely successful at Spairliners, enabling them to deliver world-class service.

Watch Antony Nardozza’s presentation at the Supply Chain Insights 2017 Global Summit at 2017 Summit Presentations.

For additional insights, listen to the interview with Joannès Vermorel, Founder of Lokad. Probabilistic Forecasting with Lokad