In December, I spoke at an internal supply chain kick-off for a group of consultants. As I prepped, I noticed a document left on the podium from the previous day. The sheet was part of speaking notes from a medical device manufacturer’s SVP of supply chain.

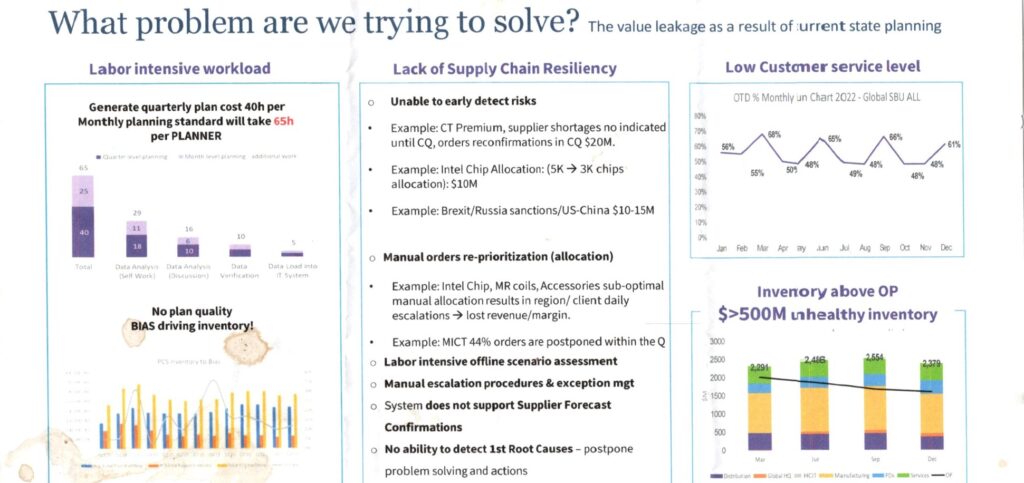

I share the sheet left on the podium in Figure 1. I loved the speaker’s question, but I hated the answer. As part of this post, I use my reaction to drive dialogue on improving supply chain planning.

Figure 1. Speaker’s Note from the Podium (please excuse my coffee stains from my travels on the document)

What I Loved

The speaker from the previous day nailed the question. His question, focusing on the value leakage from supply chain planning, is brilliant. And should be asked by everyone.

I also loved that the speaker was tracking labor productivity inputs into planning. The Company has hundreds of planners who spend sixty-five hours/planner developing the quarterly plan. Wowzah! An opportunity, I say.

History

As an analyst, I worked with this configure and make-to-order medical machinery company for twenty years. The Company is heavily dominated by lean thinking and SAP technology standardization imperatives. The company recently implemented Celonis to improve order visibility.

Supply chain planning turnover is high, the planning teams are junior, and skill building is low. Recent public reporting focuses on improving transactional automation in customer service and eliminating paper. The organization is mainly reactive, focusing on reducing order cycle times.

The organization struggles to answer, “What drives a good plan?” With a strong focus on sales execution, the planning team is caught between a lean, supply-focused operations team and an aggressive, biased sales team (biased to forecast to maximize their bonuses).

Corporate sustainability reporting touts the need to move to the circular economy while extending the lifecycle of installed equipment.

Why I Hated the Answer

My first response is that the leader’s sheet reports symptoms, not correcting the issues. With the installation of SAP HANA and SAP for over three decades, why is there no plan quality, and why is bias driving inventory? My guess is the lack of discipline lies in redefining demand management. I would start by implementing Forecast Value Added (FVA). This configure-to-order manufacturer will never be successful with an item-based forecasting model. The individual items are not forecastable. Instead, the model needs to be attribute-based and focused on platform and part-level forecasting.

The first step in risk mitigation is becoming a good trading partner. Supplier purchase orders need to be right the first time. The company should automate a network to reduce purchase order latency, track discrepancies, and drive bi-directional orchestration (alternate bill of materials and suppliers) in the build process. Business leaders need early alerting on exceptions. The current focus on indirect procurement and improving enterprise transactions is not sufficient.

With high levels of configuration and product portfolio complexity, platform simplification and part standardization would be high on my list. To reduce complexity, I would initiate a joint effort between R&D and operations.

The organization is asking to implement risk management and planning systems to make them more responsive. However, when they say “responsive,” they are advocating behavior that is really “reactive or knee-jerk” in a lean production system focused on driving the lowest costs.

Summary

Is it any wonder that customer service levels are low and inventory levels are unhealthy? In a political environment, unsure of what makes a good plan and a focus on transactional efficiency, it is difficult to drive a behavior change. The answer is not a new system or the implementation of an autonomous planning solution. The correct answer is leadership. Supply-centric functional leadership drives waste, but it is hard to rewire most organizations.

If you are interested in rethinking your supply chain strategies and approaches to supply chain planning and decision-making based on the greater availability of data, the evolution of technology, and the opportunity to make better and quicker decisions, consider signing up for the outside-in planning course being offered at the end of the month by Supply Chain Insights. The class is a six-week virtual class.

The learning is designed to be fun. Each student will be accompanied by guided GPT learning. There is one class for EMEA and one for the Americas. There is lots of hands-on homework and case studies to cement the learning. Networking across industries and companies raises the bar as an opportunity to learn. If interested, email me at lora.cecere@supplychaininsights.com or send a direct message on LinkedIn.