For the past five years, the team at Supply Chain Insights identified Supply Chains to Admire Award Winners by analyzing performance by peer group on the key metrics of growth, operating margin, inventory turns and Return on Invested Capital (ROIC).  In 2018, Rockwell Automation won the Supply Chains to Admire Award. To understand the journey, we interviewed Ernest Nicolas, head of the global supply chain at Rockwell to gain insights. In this picture, Ernest is sharing his story by speaking at the recent Supply Chain Insights Global Summit.

In 2018, Rockwell Automation won the Supply Chains to Admire Award. To understand the journey, we interviewed Ernest Nicolas, head of the global supply chain at Rockwell to gain insights. In this picture, Ernest is sharing his story by speaking at the recent Supply Chain Insights Global Summit.

About the Supply Chains to Admire Methodology

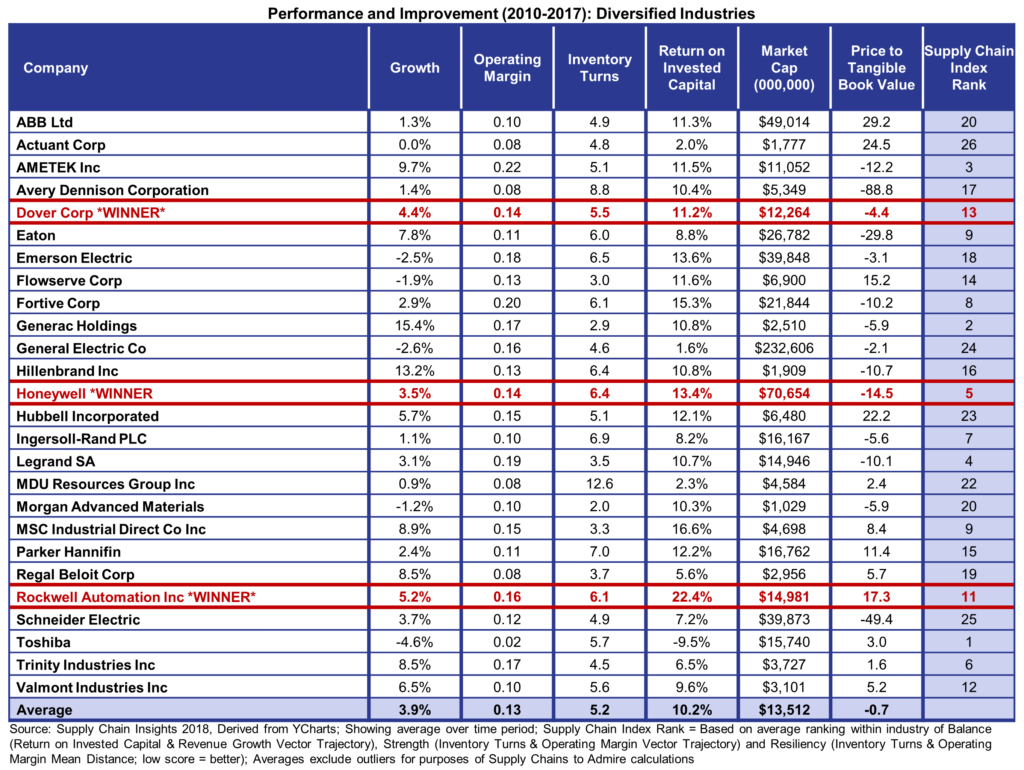

To decide winners, we analyze post-recession period performance of 2010-2018 by peer group. In Table 1, we share the results of Rockwell Automation’s performance against their peer group in the diversified industry segment. In Figure 1, we include the orbit chart of performance metrics at the intersection of operating margin and inventory turns. Note the balanced results of Rockwell Automation against their peer group.

Table 1. Diversified Industry Performance For the Period of 2010-2017

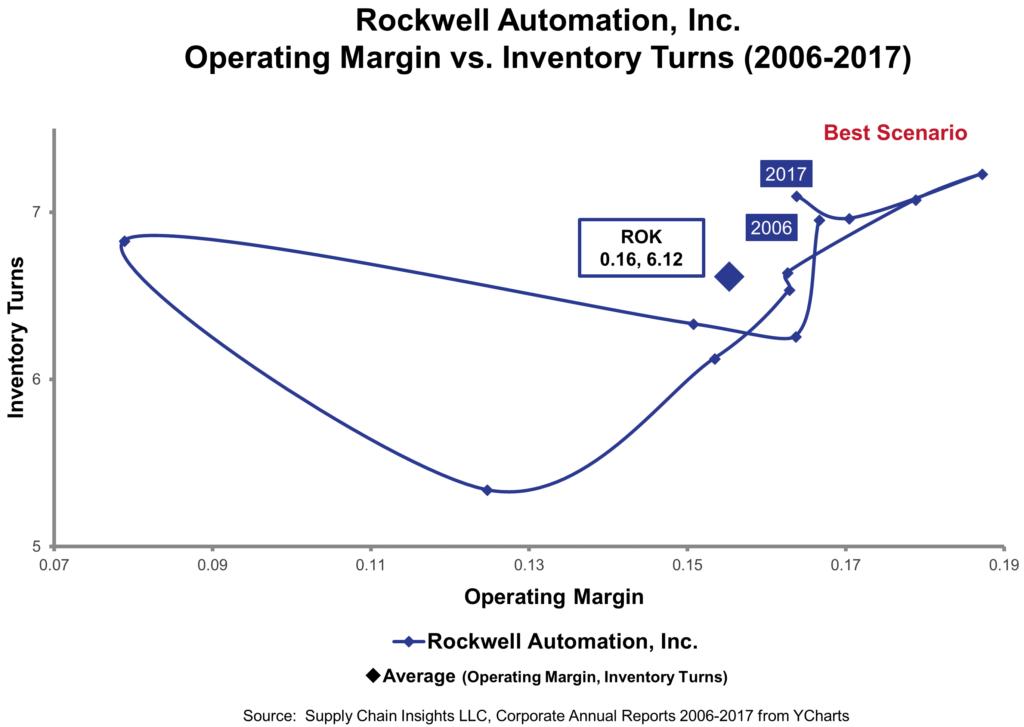

(The Supply Chain Index is a measurement of Supply Chain Improvement. The lower the number the greater the rate of relative improvement against the peer group. The concept is that the best supply chain leaders outperform their peer group while driving improvement. Check out the full analysis, for over 600 public companies by peer group in Supply Chains to Admire report.) The orbit chart in Figure 1, shows the relative rate of improvement at the intersection of inventory turns and operating margin for the period of 2006-2017. Note the general trend of improvement.

Figure 1. Orbit Chart for Rockwell Automation at the Intersection of Operating Margin and Inventory Turns for the Period of 2006-2017

Meet Ernest

Meet Ernest

Ernest Nicolas joined Rockwell Automation in 2006. He is currently the vice president of global supply chain. At Rockwell this includes all processes end-to-end except for manufacturing. In his role, Ernest owns strategic sourcing, materials planning, customer care, and logistics operations globally. He is a humble and quiet leader.

Rockwell Automation is the world’s largest company dedicated to industrial automation and information. Headquartered in Milwaukee, Wisconsin, Rockwell Automation employs approximately 23,000 people serving customers in more than 80 countries. As a B2B company, procurement management is essential. The company has over 7,000 suppliers and provides industrial automation and information products to a variety of industries in over 80 countries. The company’s sales totaled $6.3B in 2017.

Rockwell’s finished products fall into three categories: components, control, and visualization platforms. Some products–push buttons, relays, and switches–turn very quickly with high volume sales. Configured products include panel views, industrial monitors and computers, and drivers turn more slowly. At the core, Rockwell Automation produces logic controls. The company also offers engineered-to-order solutions, such as control centers and medium-voltage drives. From a manufacturing perspective, products vary significantly in complexity. Some items take very little processing time while others have a quite an extended lead time. Solutions, for example, can take from 12 to 16 weeks to manufacture.

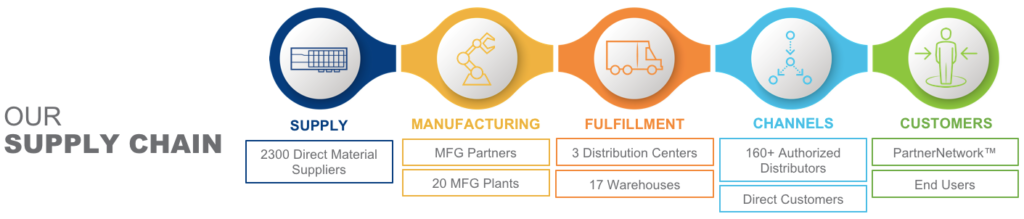

Figure 2. The Rockwell Automation Supply Chain

The company understands global manufacturers’ problems because they are one. Like most industrial manufacturers, they manage a profoundly diverse portfolio of products. In this environment, complexity is both an opportunity and a challenge. Rockwell Automation has more than 400,000 items in its catalog. A typical order is about 200 SKUs, and an average product life cycle is 20 years.

Value creation and a value-driven approach are the pillars of the Rockwell Automation model. The company’s current strategy is to bring a Connected Enterprise to life. This starts with defining value, and then combining processes, and simplifying the complex. It’s about understanding and delivering on the company’s customer’s requirements.

The Beginning of the Journey: Strategize, Centralize, and Re-footprint

In 2008, Rockwell Automation prepared to embark on something intentional: the redesign of manufacturing operations and the supply chain. At the time, the company started internal discussions on re-footprinting the organization and deploying SAP across manufacturing centers. The plan included the centralization of operations and services.

At Rockwell Automation, the vision of the Connected Enterprise is the convergence of informational technology (IT) and operational technologies (OT). The idea is to connect the shop floor to the executive suite. Within Rockwell, Ernest’s team started first to drive strategy to results. The goal was to connect upstream and downstream processes. The focus was a faster time to market, the lower total cost of ownership, improve asset utilization, and reduce risk.

The project included the centralization of SAP ERP and the augmentation with other software. The Factory Top Production Center (FTPC) is the essential core of the Rockwell Automation supply chain.

To continue driving change, Rockwell Automation also invested in design thinking. The team created global supply chain personas of essential roles. Supply chain personas guided the global manufacturing re-foot printing efforts and landed the company at the very top of the Supply Chains to Admire ranking.

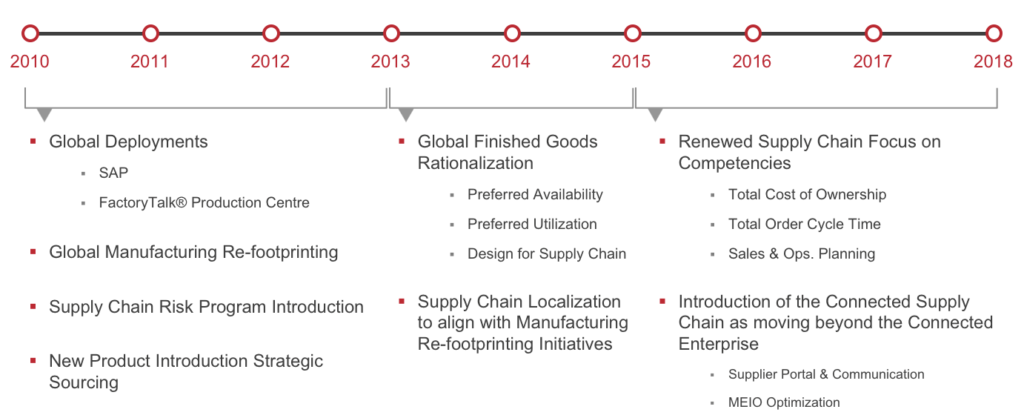

Figure 3. Rockwell’s Automation Journey

Historically, the Rockwell Automation supply chain organization included materials planning and engineering of new products but did not include strategic sourcing. to change this, the company chose to take engineers out of design function and trained them on the fundamentals of supply chain and strategic sourcing. The company also taught them to understand the basics of negotiation and risk management. The goal was to generate scale while ensuring that they leveraged their preferred suppliers, and taking some of the products’ cost upfront. That was a significant shift in the Rockwell Automation previous approach to a supply chain.

Historically, the Rockwell Automation supply chain organization included materials planning and engineering of new products but did not include strategic sourcing. to change this, the company chose to take engineers out of design function and trained them on the fundamentals of supply chain and strategic sourcing. The company also taught them to understand the basics of negotiation and risk management. The goal was to generate scale while ensuring that they leveraged their preferred suppliers, and taking some of the products’ cost upfront. That was a significant shift in the Rockwell Automation previous approach to a supply chain.

Step Two: Rationalize, Localize

In 2013, the company drove scale for finished goods. They started to preferred metric availability and preferred utilization through sales to better understand order tracking along with the analysis of customers’ orders were using preferred products. Rockwell Automation provided incentives sales to help motivate their sales team.

The company also started to localize order fulfillment . Looking back, one strategic move Ernest regarded as questionable is the company “localizing to localize” without questioning whether it was the best fit for sourcing. However, localized sourcing shortened leadtimes and improve responsiveness.

Bringing It All Together: The Connected Supply Chain

In 2015, the company began focusing on total cost of ownership, order cycle time, and sales and operations planning.

The total cost of ownership analyzes the total costs of the buying decision. The company had to ensure they were balancing everything appropriately, not only considering just purchase price variance or cost down but all the elements of the source-plan-make-deliver cycle. (In the case of Rockwell Automation, it’s plan-source-make-deliver because of the structure of the organization.) Ultimately, the company made sure they were taking into consideration all the various elements and the impact they will have on different functions of the process supply chain.

Total order cycle time was about going back to the cash and thinking about ways to reduce the time. This methodology was especially crucial for Rockwell Automation global customers, whose impact was notable since it didn’t have the benefit of their distribution network. The company focused on sales and operations planning comprising one supply chain. They also focused on lowering the walls of the silos: getting logistics, sourcing, supply chain planning to work on being globally inclusive. The company embraced cross-functional thinking, became much more end-to-end, and leveraged its cross-functional talent. All of these steps led to the final push: the introduction of the connected supply chain.

The next step was modernization. At this point Rockwell Automation was ready to redesign supply chain hordes, to fundamentally change its business process, and to leverage technology.

The Result: Show Me the Money

Ernest started the journey with some realistic expectations: a sustainable return, a reduction in cost, and improved supplier performance. Figure 4 shows the improvement in the important metrics: supplier performance has surpassed the expectations in all three dimensions. Customer service also exceeded its targets. As Rockwell Automation learned and understood their capacity and segmented their data, they saw significant improvement in on-time fulfillment rates, product lead time drops by 50%, and past due orders (ten-fold improvement).

Figure 4. Quantifiable Results of Rockwell’s Automation Journey

As shown in Figure 4, annual productivity numbers climbed steadily since 2011.

As shown in Figure 4, annual productivity numbers climbed steadily since 2011.

Where to Next?

The company has achieved clearer visibility into plant operations by leveraging their own products. They are using real-time data to make more profitable decisions faster. The team has standardized processes across all the facilities. As a result, best practices are more accurately identified and proliferated using consolidated analytics. The company is now focusing on cognitive sourcing, demand-driven procurement, and enhancing visibility. The next step is expanding the supply chain to improve the visibility of upstream and downstream, which will bring the connected enterprise to a new level: The Connected Supply Chain.

Our Take

Rockwell Automation is a case study of a company working a long-term plan focused on improving flows for the customer. The focus on design-thinking and supply chain personas grounded the process to ensure delivery of results.

Read more Supply Chains to Admire Stories:

BASF

L’Oreal

Sandisk