When it comes to the management of inventory in value chains, frustration abounds. Executive after executive laments they have purchased many technologies, and sponsored many projects to reduce inventories, but they are not seeing results. I have been studying the evolution of inventory technologies as an industry analyst since 2002. This week, I published an in-depth analysis on the topic. In this post, I share my reflections along with seven misconceptions.

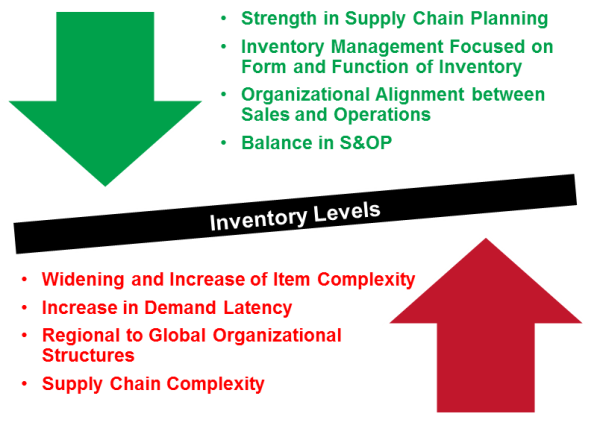

Figure 1. Inventory Levels

The supply chain is a complex system with increasing complexity. Inventory is the culmination of many business decisions. Few companies manage their supply chains end-to-end; and as a result, they cannot manage inventory holistically. Only 10% of companies are making progress at the intersection of inventory turns and operating margin. There is no silver bullet. It is truly a case of process, people and technology. Notable exceptions, making improvements at the intersection of inventory turns and operating margin, are companies like Carlsberg, Cisco Systems, Hershey, and Novo Nordisk.

Tracking Progress

The supply chain leader manages performance at the intersection of inventory turns, operating margin and customer service. While we cannot access customer service levels for public companies, we can measure progress at the intersection of operating margins and inventory turns.

At Supply Chain Insights, this is our passion. We are systemically evaluating each industry in the Supply Chain Insights Metrics That Matter series of reports. Last Thursday, we published an in-depth analysis of the pharmaceutical industries and in May, we will focus on progress in the chemical industry. This is in preparation for the 2015 Supply Chains to Admire Report.

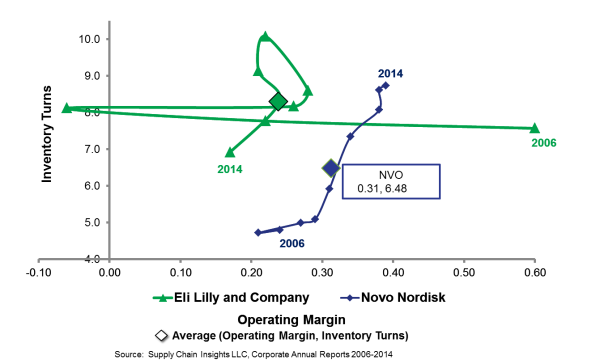

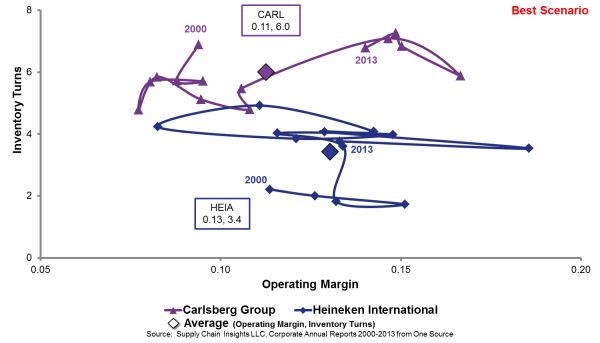

In Figures 2 and 3, we share orbit charts of progress. Let’s take a closer look to see what progress looks like. In figure 2, we compare Novo Nordisk versus Eli Lilly. Note the improvement in inventory and operating margins by Novo Nordisk and the lack of progress by Eli Lilly. In parallel, in Figure 3, note the progress by Carlsberg, and the lack of progress by Heineken. This type of benchmarking is the most powerful in the comparison of like competitors.

Figure 2. Novo Nordisk vs. Eli Lilly

Figure 3. Carlsberg vs. Heineken

The Inventory Management Journey

Why is progress so hard? Over the last decade, most companies went through a multitude of changes. The increase in the item complexity, the lengthening of demand latency and the building of global supply chains with greater in-transit inventories top the list. To counteract these business shifts, companies have invested in Enterprise Resource Planning (ERP) and Advanced Planning Systems(APS), focused on projects in Lean Flow, and driven maturity programs for Sales and Operations Planning. These efforts are not enough.

The business drivers have outpaced the company’s ability to manage inventory through new technologies and processes. Why? While we have talked about collaboration, Vendor Managed Inventory (VMI) are not connected to enterprise systems, and less than 5% of companies have deployed multi-tier inventory optimization software to support a continual process (as opposed to an ad hoc) analysis to set inventory targets. Network design concepts are gradually gaining acceptance, but too few design their networks. And, when they do, the focus on network design is still on bricks and mortar–where to put manufacturing and distribution locations–not on form and function of inventory, and the design of inventory flows.

Seven Misconceptions

I find that when it comes to the management of inventory, misconceptions abound. This includes:

- Inventory Management Is the Same as Replenishment. Inventory management and replenishment are separate, but interrelated processes. While inventory management includes the design of inventory strategies to set inventory targets including the execution of supply chain processes to design and manage the form and function of inventory, replenishment is a about flow. Replenishment is usually push-based logic, based on a series of rules, based on dependent, as opposed to independent, demand. As a result, traditional replenishment logic amplifies and distorts the demand signal. The greater the demand error, and the greater the supplier volatility, the greater the need for multi-tier inventory management.

- Inventory Is a Cost to Be Managed. Finance wants to actively manage inventory. A frequent mistake made in the management of inventory in the extended supply chain is a blanket reduction—a corporate mandate to reduce inventory— without rationalizing the requirements for inventory in the value chain. Inventory should never be managed to a financial target. Instead, it needs to be based on the requirements of customer policy and the supply chain strategy. For many, this understanding is the toughest to close. Finance needs education.

- The Management of Inventory Does Not Need Technology. To get good at the management of inventory, companies need technologies. The supply chain is a complex system that cannot be adequately managed through calculations on a spreadsheet. As a result, companies need to blow up their spreadsheet ghettos within the organization and challenge the supply chain team to think more holistically about the role of inventory in the market-driven value network.

- I Can Use New Technologies without Changing My Planning Organization. The use of new technologies requires time for planners to use them, and when implemented correctly leads to a new set of business processes. Do not make the mistake of buying and installing the technologies, but not getting the benefit because the planners did not have adequate time to plan, or you have not taken the time to rethink the processes to use the new technologies.

- Implement with Knowledgeable Resources. At first when you read this recommendation you might say, “DUH!?” However, let’s face facts. There are too few people in the world who are really knowledgeable about inventory management software tools. While many consultants will talk about inventory, we find few to be knowledgeable in the technologies. Instead, we find the technology’s provider to be the most knowledgeable on the use of the technologies. There are also a few boutique consultancies around the world that have built strong teams around inventory optimization. These are usually small, and focused consultancies with a strong inventory heritage.

- The Market Leaders in Inventory Management Technology Have the Best Solutions. The companies with the greatest market share—Oracle and SAP—have the weakest references. While both Oracle and SAP will hotly debate this fact, we find a growing gap between the vendors’ perception of the use of their solutions market and satisfaction levels of their clients.

- All of the Solutions Have the Same in Functionality. There are major differences in the technologies to manage inventories in the extended supply chain. It is too complex to be described in a four-box model. As a result, companies should buy inventory management technologies based on process requirements, IT standardization and cultural fit. While many think that solutions with a common name—technologies purchased from a common vendor—are integrated, often the situation in the market is vastly different. Most of the inventory technologies have been sold and resold multiple times in the market, with many best of breed solutions having better integration than the ERP providers touting integration.

The market for multi-tier inventory management was overhyped and largely underdelivered in the period of 2005-2007. Due to market size, and the highly competitive and fragmented market, the levels of R&D investment by technology providers has slowed. As a result, buyers should buy based on today’s functionality.

These are my thoughts. Any misconceptions to add? I look forward to hearing from you! We will be covering this and more at the Supply Chain Insights Global Summit. Will we see you there?

This is my third year of hosting the annual Supply Chain Insights Global Summit. I hold the event at The Phoenician in Scottsdale, AZ on September 9-10. It is an exclusive group of 150 supply chain leaders.

Baxter and Sawyer will be there! The robots are featured in the digital showcase on the opening night of the event.

The Summit agenda focuses on even themes:

- Supply Chains to Admire. At this conference, we will unveil the results of our second study on supply chain performance and improvement. In this session, you will gain an understanding of which companies have driven the fastest improvement and highest level of performance. Understand what is possible as you listen to stories of these supply chain leaders.

- Race for Supply Chain 2020. Two leading economists—Richard Florida and Pankaj Ghemawat—will share insights on the future of world trade and the changing nature of world demographics. The world is not flat and there is more friction across borders than there was prior to the great recession. Learn what the future will hold and how to best prepare.

- Power Growth through New Technologies. Mobile. Augmented Reality. Corporate Social Responsibility. The Collaborative Economy. 3D Printing. Cognitive Learning. Robotics. There is a flood of new technologies and approaches to change traditional supply chain models. Join us the afternoon of September 9th, to understand how companies like Jabil, Green Eileen, and Sidecar are using these new technologies to power growth.

- Digital Supply Chain. Gain an understanding of what is a digital supply chain, and learn more about the capabilities of new technologies to drive innovation. Join us at the digital showcase during our Welcome Reception on September 8th to get hands-on experience and gain exposure to case studies by supply chain leaders that are driving outside-in transformations.

- Supply Chain Transformation. Join us the morning of September 10th to gain insights on how General Mills, Intel, Lenovo, Wright Medical, and Seagate have driven supply chain transformation. This session will end with a panel discussion of leading experts sharing insights on building demand-driven processes as participants share their insights from the Supply Chain Insights planning benchmarking work.

- Power of Outside-in Processes. If you have played the beer game, and are looking for a new way to help teams understand the complexities of supply chain management, we have designed the afternoon of September 10th for you. Spend the afternoon enjoying playing the new simulation game built by Sterling Simulation and Supply Chain Insights to demonstrate the power of outside-in processes. Network with your peers on the insights and relax under the Arizona skies as you wrap up a couple of intense days with your peers at the final reception.

- Network with Leaders. This is the event where supply chain innovators talk to supply chain visionaries. It is unlike any other conference. If you are looking to stretch your thinking, you will want to put this conference on your calendar.

Registration for the event is now available, and there is a special discounted room rate at The Phoenician if you register early. See you there?

All the best on your journey for supply chain excellence. Thanks for reading the Supply Chain Shaman blog, and I hope to see you at the Supply Chain Insights Global Summit…

As we move towards ‘The Third Act of Supply Chain Planning Software‘, my focus is to help line-of-business users make data-driven decisions. This is why we continue to fund surveys which we share openly and freely. Our mantra is “You give to us, and we give to you.” We are currently finishing up research on S&OP and Inventory Management technologies. Take our surveys. We never share the names of respondents, and we always share the results. The results will be shared in open roundtables with supply chain leaders. Here are the links to the studies:

Inventory Management

Sales and Operations Planning

_____________________

About the Author:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for excellence.