The booths at the National Retail Federation (NRF) on January 12th-14th will shine brightly with AI plastered everywhere. However, based on my discussions with the technologists, the real improvements to drive value will be few and far between.

Venture capitalists are high on Artificial Intelligence (AI), and over-exuberant professors with shiny new models are jockeying into position to get rich. Building a software company is hard work. I am speaking to many that are ill equipped.

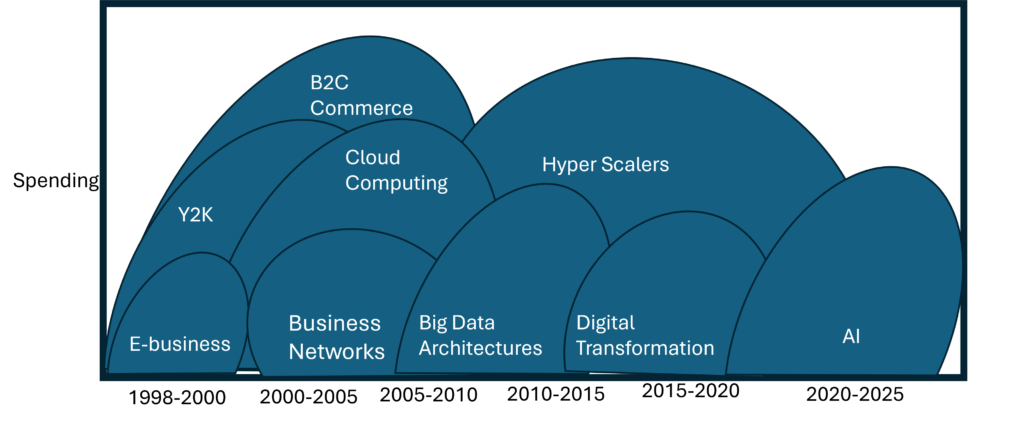

We are in the middle of a hype cycle that in my mind looks like the image in Figure 1. The industry has had little value from digital transformation and business networks. (Most of the business networks were hollowed out by venture capitalists or purchased by opportunists. The business network market is in need of innovation.) The big data architectures are often present in the current “AI offerings.”

My problem is that we move through these hype cycles with little accountability for spending and with a major opportunity cost to not redefine work. The supply chain planner role is the most dissatisfied of any employee in the supply chain, but most focus on improving engines using AI into conventional work processes. This will not help. The opportunity is to rethink planning.

Figure 1. Supply Chain Hype Cycles

Preparing to Sort Through the Hype

As you pack your comfortable shoes into your case for the Big Show, do some the homework. Come prepared to engage and push past the hype. How to do this? When entering a booth, consider asking:

What problem do you solve?

What role does AI play in improving outcomes?

How do you drive value?

In the discussion, don’t be shy. Get ready for a dialogue to get past evasive words, an avalanche of acronyms, aggressive salesmanship and hand-waving. Try to gain an understanding of how technological advancements can improve work. Most of the answers will fall into categories:

- Engines: The improvement of the math in models to improve decisions. Techniques include machine learning, pattern recognition, and narrow AI. The use of python and big-data architectures enables the ingestion of unstructured and streaming data that can move the model from inside-out (using enterprise data) to outside-in (use of market data). The questions to ask are, “How does the improvement of engines improve work? How do you know you have a better outcome or decision?” Yawn and walk on if the answer is improving demand error or reducing inventory levels.

- Agents: Robotic agents, agent-based optimization, and chatbots formulate suggested actions from query, market shifts, or exceptions. Using deep learning and other techniques, the agents drive insights. The building of data listening platforms to enable teams to answer the questions that they did not know to ask. The questions to ask are, “How do I know if it is a good answer? How do I train and maintain the logic?”

- Data Management: Supply Chain leaders speak of dirty data as a barrier to improving supply chain outcomes. In the real world, data will never be pristine, clean, or odor free. The goal needs to shift to maximize the use disparate data. Pattern recognition and machine learning enables constant learning and cleaning. 80% of the data that surrounds the supply chain is not used. The homework is to bring a list of the data that you think could drive better decisions to the conference and ask the technology company for insights on how to best use different forms of data.

- Policy and Rules Management: Ontological frameworks enable complex rules and policy management. While traditional rule engines for decisions like allocation and Available to Promise were too simple with if-then models. Ontological frameworks enable constant learning and policy adaptation. Ask for use cases.

- Discovery: The building of data listening platforms allows teams to answer the questions that they did not know to ask. The use of large language models to improve listening, the ingestion of large amounts of unstructured data and images and write recommendations. Think about the building of listening posts of rating & review data, continuous listening of call center transcripts, analysis of contracts, or the continuous analysis of supplier certificates for digital passport/Scope 3 emissions.

Wrap-up

Before you hit the show floor, educate yourself. Don’t talk generalities. Listen closely for words like the knowledge graph, ontological rules and policy management processing, pattern recognition, large language models, and narrow AI. As the technologists spin their stories in their booths characterize their offering into engines, agents, rules automation, listening, and discovery.

Don’t let the technologist spin the story of AI for AI without pushing for the answer to “so what, who cares?” Force the technologist to answer the question of “How does this solution improve work and drive improved outcomes?” Most are only updating the engines in old jalopies. In my opinion, we need to do better.

See You on December 5th?

On December 5th, Supply Chain Insights is hosting a small event at Georgia Tech to share the results of a two-year research effort to connect financial metrics by industry to supply chain performance to drive value. The session is a roundtable format–no sponsorships, vendor speeches, or pay for play pitches.

At the session, we will discuss the choice of metrics for a balanced scorecard to improve market capitalization/employee by industry. (Did you know that improvement in the supply chain drives 50-70% of this value metric? Or that a focus on cost reduction can actually undermine value creation?)

The session is open to manufacturers, retailers, consultants, and academics. At this session, we will launch the “supply chain fundamental score” (a simple measurement to determine value generated by the supply chain as compared to the peer group). Each attendee will receive an orbit chart packet with a comparison to their peer group. Drop me a DM on LinkedIn if you want to attend. The session is from 9-4 on the Georgia Tech campus, Atlanta, GA.