Timeless: not affected by the passage of time or changes in fashion.

Last week I was on vacation in the Caribbean. I moved on island time. It is a slower, more relaxed pace. In the process, I thought a lot about the concept of time and how it affects our daily lives.

Last week I was on vacation in the Caribbean. I moved on island time. It is a slower, more relaxed pace. In the process, I thought a lot about the concept of time and how it affects our daily lives.

Supply chains are anything but timeless. At a company, individuals define supply chain excellence based upon their own purview of time. It is usually very different.

Often when I visit a client, I witness circular discussions of supply chain excellence. Why? Simply put: each person sitting at the table has a different view of time. Typically, people fall within five camps:

- The Transactional Thinker. Teams finishing up an ERP project often think in terms of transactions. Their world view is very short term of days. This is often the view of IT.

- The Financial Planner. The role of finance is often laser-focused on the quarter, and the impact of quarterly decisions. The balance sheet impact drives the decisions.

- The Production Planner. Manufacturing cycles drive the cadence of production planning. (The time to cycle through products in production along with change-overs, clean-out periods, and production runs.) This is a very operational view, typically focused on a specific manufacturing plant.

- Order Management and Customer Service. Order duration and the time to process an order define the view of the customer service team. (The period of orders being firmed against inventory.)

- Supply Chain Planner. In contrast, the supply chain planner focuses on the operational period (near term), the tactical period (mid-term) and the network design or strategic period (long-term). These are different for each company and driven by the decisions on asset utilization, maintenance planning, seasonal builds, contract manufacturing, substitute item logic, and forecasting trends.

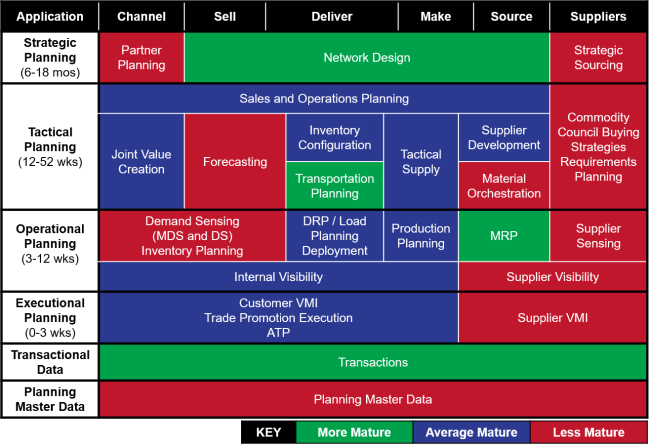

The key for supply chain excellence is to successfully align the cycles. The current technologies divide time into strategic, tactical, operational, executional, and transactional planning horizons. Each serves a different purpose within the organization. I have never worked with a company that is mature in all of the elements. These are maturing. In Figure 1 I share a client example. (The green represents mature processes, while the blue represents evolving capabilities, and the red indicates immature process capabilities.) No two companies define the time horizons the same. They vary widely driven by the cadence of business decisions.

Figure 1. Planning Time Horizon Definitions

Hold on to Your Hats

While planning thinking is maturing, new technology capabilities will force a redefinition and add to the confusion. In this process, hold on to your hats. Technologies are asking teams to redefine time in three ways. Let me explain.

- Real-Time Planning. The Internet of Things (IoT) discussion is creating a frenzy about real-time data. Our planning processes today are batch processes on latent data. Streaming data architectures and the use of real-time data is a new chapter in supply chain processes. I think we need to control the hype. Not all data should fly first class. There are cases where real-time data adds value–digital manufacturing, telematics for transportation, GPS data for precise location–but, by and large, planning is not a real-time process. And I would add a bit of caution. Should it be? Will real-time data introduce nervousness into a complex system?

- Plan by Design. In contrast, the network design technology providers are pushing a concept of “plan by design.” I like this concept. Let me explain. The thought is that a strategic network planning tool will set the “Blueprint” and “Planning Set Points” for tactical planning. Tactical planning runs more frequently than network design, but the concept is to integrate the output of the network design tools to improve tactical planning. I think this idea has great merit. However, the caution is that this concept is new, and the marketing rhetoric of supply chain vendors can make this confusing. In your discussions with the planning vendors get clear on the definitions, and frequency, of strategic and tactical planning.

- Concurrent Planning. Traditional supply chain planning processes were defined in the 1990’s when technology companies (the teams building the solutions) were limited by 32-bit architectures. Today memory is no longer a limitation. So the question is, “How should we use memory in planning?” Should we perform operational and tactical planning simultaneously reducing the need for distinctly different planning horizons? Or should we do a better job in each time horizon with better handoffs between the horizons. (Better visibility between the planning horizons.) The answer to this question is tricky. Be careful. There are many schools of thought:

- Cognitive Computing Purists. The cognitive computing purists believe that we can reduce all the definitional boundaries between planning horizons and processes and have one large planning model. I think this is dangerous.

- Divisionalists. ERP vendors like SAP believe we can take operational planning into the ERP instance and more closely couple ERP with transactional data. This is the current thinking on the redefinition of the SAP platform and the evolution of SAP IBP. I also think that this is problematic.

- Traditionalists. The traditionalist believes that a tactical planning process and an operational planning process are distinctly different even though the technology boundaries are no longer present that the business requirements drive a need for different planning horizons.

- New Age Thinkers. Many of the cloud-based solution providers are making the argument to merge operational and tactical planning horizons.

As I listen to the arguments, I am not sure. My frustration is that most discussions tend to generalize supply chain requirements. One thing I do know is that no two supply chains are alike. My belief is that if you are an asset-based global supply chain (think about the need for assets in process-based companies) with a need for cross-company shipments (especially across geographical regions on ocean containers) that you should never blur the lines between operational and tactical planning horizons. However, if you are a regional company in a discrete make-to-order environment, blurring the lines between operational and tactical planning may make sense. I think that the synchronization of strategic and tactical planning makes a lot of sense, but I don’t think that planning is ever real-time. (By definition planning is not a real-time process.)

In contrast, I do not believe you should ever push operational planning into an ERP transactional environment. It is for this reason I think that the current SAP architecture is flawed. I believe as more and more companies struggle with the implementation of SAP PPDS in an ERP instance, frustration will grow. Why do I feel this so strongly? Let me explain. The average company has five ERP instances. Very few companies have a single instance. Who will benefit by SAP’s shift? The movement of production planning by SAP into the ERP instance will benefit companies like Kinaxis and OM Partners. The wild cards will be E2open and Oracle’s new definition of cloud-based planning.

I welcome your thoughts.