My aged hand drapes the barre on the celebration of Global Ballet day. Dutifully, no matter how bad I performed in the last class, I return to the barre, extend my right hand and start a new class. There is a soothing familiarity to refine the moves that defy my capabilities.

My aged hand drapes the barre on the celebration of Global Ballet day. Dutifully, no matter how bad I performed in the last class, I return to the barre, extend my right hand and start a new class. There is a soothing familiarity to refine the moves that defy my capabilities.

On these days, like most, my teacher sighs and reminds me to listen harder to the music. I frustrate her. Her face scrunches in pain as I lead the barre with the wrong tempo. The reason? I lack musicality—the ability for the music and the dancer to become one—and struggle to interpret the changes in tempo or a variation in rhythm. I love to listen to the music, but struggle to move my body fluidly through the tempos. To try to get better, I have enrolled in piano classes and actively listen to my metronome.

Is The Supply Chain Out of Rhythm?

So, why might you ask is Lora telling you this story? On a supply chain blog? Let me explain. As I struggle to build musicality, I think about the rhythms and cycles of the supply chain. Yep, I am that geeky kind of gal.

My mind races. As I get bored with class, I think about recent client experiences and how the rhythms are changing—some are slowing like a beautiful adage while others are accelerating with greater variability like a petit-allegro with an almost deafening staccato-like pace. In all cases, with my clients, I find that the internal supply chain is out of step—lacking musicality with either the channel or the supplier base. In short: business teams are out of sync with the markets. The problem? The markets are more variable and excellence requires synchronization. Most have focused on integration–connecting data–versus synchronization. The difference is more than nuance. Here I exlain.

Table 1. Supply Chain Rhythms and Cycles

Reflection

Reflection

I firmly believe that the movement of IT to report to the CFO has slowed progress in supply chain innovation. The reason? Most of the CFOs that I work with view the supply chain with a transactional mindset. Their view of data and workflows is focused on efficiency and driving the lowest cost. Few understand resiliency, buffers, and the need for the adaptive supply chain. In most cases, the efficient supply chain is not the most effective.

As the leadership team maturity transgresses through the evolution of the supply chain as a function to the understanding of the supply chain as an outside-in cross-functional process, there is tension. Consequently, the term supply chain is politically charged. (Most CFOs that I work with would be well-served to take a course in supply chain planning. However, I find their egos are large, and their time scarce: making this unlikely.)

The CFOs that I work with lack an understanding of supply chain planning. Their world view is currency-based planning at a brand level while supply chain planning is volume-based at an item/location level. (As companies become more mature, the definition of location changes moving from a ship-from location to a ship-to-location to be more customer-centric.) The focus on ERP and connecting data without clarity of policy and workflow is detrimental. In addition, as a result of the CFO’s agenda, the organization’s focus is usually on the management of enterprise data without an understanding of demand latency (time for consumption to translate into order-based replenishment).

Common Mistakes

In the journey, companies make many mistakes. These throw the supply chain out of balance. Wrecking the rhythm and cycles… Unfortunately, there is no ballet mistress with a cane forcing refinement of a dance that is not understood. As a result, companies struggle:

The Supply Chain Needs to be Real-time. One mistake that companies make is asking for processes to be real-time. While processes can be updated and refined through real-time data, not all processes need to move in real-time. Instead, they need to operate at the speed of business with zero latency. While real-time data offers great promise, the benefit is only actualized if the data is properly used. The focus only on real-time data introduces nervousness into the system.

I Want An Integrated Supply Chain. When I hear this, I ask, “Integrated to what and why?” For many, this is code for “implement ERP.” Instead, the goal should be synchronization and data portability to drive interoperability. Synchronization moves data across time horizons through consumption logic and workflows while harmonizing calendar and planning master data (item data, cycle information and data translation).

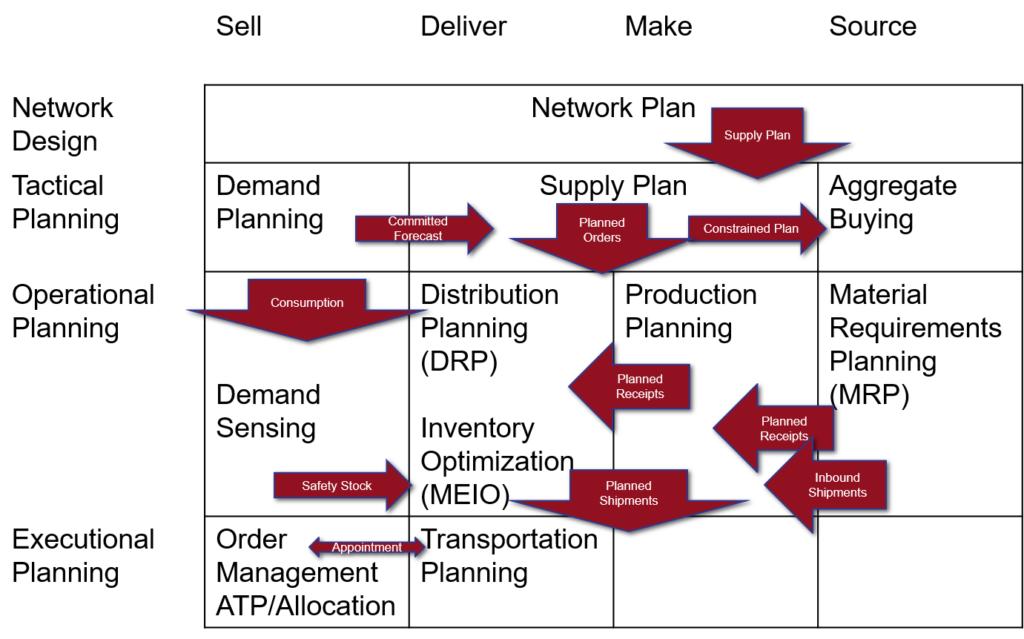

Figure 1. Supply Chain Planning Workflows

What is the difference between integrated and synchronized planning? While integration moves data from point A to point B while data synchronization adds policies (and rules) to align supply chain execution to business strategy. The number of instances is numerous, but to start the discussion, let me give some examples:

What is the difference between integrated and synchronized planning? While integration moves data from point A to point B while data synchronization adds policies (and rules) to align supply chain execution to business strategy. The number of instances is numerous, but to start the discussion, let me give some examples:

- Seasonality. If a product has strong seasonality, replenishment needs to be mapped by item into production planning. If data is connected without the translation of the patterns of the replenishment and seasonal flows. It would miss the synchronization of the different streams by policy to the outcome.

- Demand Consumption. Monthly demand needs to be consumed into daily schedules based on rules-based consumption. The consumption needs to be in sync with market sales and shown as an indicator in demand management as an exception to help guide corporate discussions. Consumption is managed by rules, policies, and optimization. These policies drive replenishment.

- Freeze Duration and Production Logic. Production plans require a focus on cycle stock management. The focus is to freeze the schedule for a short duration to manage cycle stocks. This production logic is key to the management of inventory policy. While most companies have worked on safety stock logic, they have not fully thought out and implemented cycle stock policies and logic.

End-to-end: When I hear the words “end-to-end”, I smile. I then ask the speaker to describe, “What is end-to-end?” For most, it a supplier to the factory or a factory to a customer. …a very limited view, but one that communicates the current level of business pain.

Ninety-five percent of supply chains are designed from supply to the channel. The problem? As the channel changes, if the supply chain does not start with the customer, it quickly becomes out of step. Companies have the wrong data and struggle to focus on the customer.

A few answers espouse my definition “as bi-directional flows from the customer’s customer to the supplier’s supplier.” Most business leaders are linear in thinking and limited in scope (structurally encased by a functional understanding of supply chain excellence).

With the evolution of the supply chain as a function, the answers become more limited. More mature supply chain end-to-end thinking focuses on the flows of products, cash, information and demand from the channel to the organization and seamlessly through the organization’s network. This shift as shown in Figure 4 is not trivial. It is overarching. The supply chain starts and ends with the customer and there are no alignment issues between commercial and operations teams.

Figure 4. Outside-in Processes

Clear Definitions. I want visibility said the client. “You want visibility of what in what time dimensions?” I asked. He did not know. At the next client, the team stated that they wanted a control tower, and when I asked, “What they wanted to control?” They were not sure. Teams bandy terms around without definition. The conversations go round and round. Leadership groups throw around concepts without running the terms to ground. As a result, the plans to execute process changes run afoul.

Summary

As we move into the new year and kick-off the new decade, which is the fifth decade for the evolution of supply chain processes, we need to learn from the past to question the future. In the process, we need to be honest. Over 95% of companies are stuck at the intersection of growth, cost, customer service, asset utilization, and inventory. The number one question that I am asked is how to improve customer service. With the increase in complexity, supply chains are becoming more and more non-linear. The process requirements of 2020 are fundamentally different than those of 2000; yet, the processes have not changed. As a result, it takes time to get it right. My advice? Drive conversations from the superficial to gain clarity to make the next steps actionable.

So when the CFO asks for an integrated end-to-end supply chain strategy, smile and then take the discussion to a more actionable level. Use it as a time to educate. Don’t make the same mistakes that we made in the last decade. Push forward. I know it is hard.

I look forward to hearing your feedback.