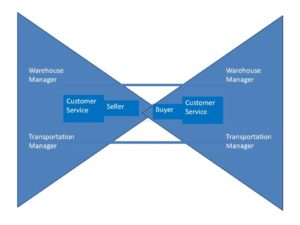

With the current economic uncertainty, is it time to step out and to make lasting and meaningful supply chain relationships and unleash the opportunities in the end to end supply chain? However, before you take that step, do you need to broaden the knot in your bow tie?

I have been writing about supply chain collaboration for the last fifteen years. The term is bandied about. Supply chain strategy documents drip with it. Conference presentations are ladened with the concept. They include phrases like collaborate with your trading partners, build collaborative networks, implement collaborative technologies, and collaborate to build value…. Can you imagine how unpopular I am, when I give clients the feedback that “true supply chain can only really happen when you have a lasting win-win value proposition.”

My goal of this blog: stop the madness. Reset expectations. Stop fooling yourself. What most people call collaboration is really data sharing. Collaboration can only really happen when you have a lasting win-win value proposition; and in this changing world of power structures, constraints, and demand volatility, this is harder than ever.

By and large, we have failed in the creation of true collaborative relationships in Supply Chain Management (SCM). Here I share insights on how to turn the tables and make true collaboration—a lasting win/win value proposition – a reality. It is enabled by technology; but technology alone is not sufficient.

Peeling Back the Onion

In reviewing history, there have been a lot of well intended initiatives. Before we look at how we go forward, let’s examine what went wrong and how we learn from history:

CPFR: Continuous Planning Forecasting and Replenishment failed for three reasons. Aspirations were greater than capabilities. (Retailer’s forecasting processes and demand accuracy was not up to the test.) It was labor intensive; and the planning processes was not connected well to execution. It was over-hyped by industry professionals which delayed a correction course for salvation.

Scorecards: This effort failed to reach potential due to a lack of standardization and connection of the output back to buying behavior. E.g. Over 95% of companies do not align scorecards with commercial buying processes. As a result, they are there (often there are many), and they are they are talked about; but they fall short in driving TRUE collaborative behavior.

Collaborative Design: Collaborative design efforts have been the most successful tactic for collaborative SCM, but there have not be escalated to strategic importance. They are growing in importance in companies green initiatives and micro-marketing efforts for packaging design; but most companies do not know how to break down the walls between R&D and supply chain to make collaborative design systems work for them more holistically.

VMI/SMI: Vendor managed and supplier managed inventory programs have also had limited success. Why? For 80% of companies the focus was on SHIFTING inventory responsibility as opposed to improving value in the value chain. Companies that have gone the extra mile to focus on reducing demand latency and downstream data sharing have achieved the greatest advantage.

An additional problem has been the labor required to support VMI initiatives and the sequence of VMI orders in the order stream. A little known fact is that VMI orders while usually the most strategic, get a lower priority on tight inventory. Why? Due to the amount of time to calculate replenishment constraints, they are usually processed as the last orders in the day letting orders processed earlier in the day drain tight inventory requirements.

Kaizen Events: Kaizen events where two parties are focused on improving the value chain through lean methods can be effective if both parties are aligned against the same goals, but if they are not, it is merely another program. While, I am a big supporter of this type of initiative, it requires a focused team and aligned objectives which are usually tough obstacles to conquer.

Building True Collaborative Practices

So, what does it take to have true collaboration? The key is to broaden the knot in your bowtime, align goals and develop deep cross-organizational relationships. While traditional approaches have focused on data sharing or transactional efficiency, the use collaborative technologies allow you to connect people to people across the value chain to build more long-lasting relationships. Consider three tactics:

Consider three tactics:

If You Are a Buyer. Put Your Money Where Your Mouth Is: If you are a buyer, tie scorecards to buying decisions through multi-variant bid techniques from companies like Ariba, Emptoris, Oracle and SAP. Reward suppliers for supply chain excellence, contribution to open innovation and cash-to-cash improvements. Tie scorecards to real money and review them monthly.

If You Are a Seller. Teach Sales How to Pitch a Winning Menu: While most incentives for sellers are volume based, work with sales to build a menu of options that can reduce costs and improve the trading relationships. Experience shows that this is not the place for dictating policy. It is impossible to implement standardized practices that can be adopted equally by all trading partners. Instead, focus on a menu program where you incent the partner for buying like option A, option B, option C and then reward the trading partner for taking these options through the use of buying incentives. Include tangible items like shipping programs (backhauls, continuous moves, private fleet utilization, etc) to reduce costs and improve carbon footprint, use of standards, taking new products, quick unloading of shipments, payment schedules, and sharing of downstream data.

Broaden Your Bowtie: Conceptually this concept has been around for along time, but it has been difficult to execute. Just too time consuming to connect trading partner warehouse managers, traffic managers, customer service personnel, etc. Not any more. Use social technologies like Lithium and Jive as a core on partner extranets to connect people to people. Complete with pictures, interests, microblogging, instant messaging, and fan pages. Who says that supply chain cannot be more social?

One of the most successful collaborative efforts that I ever accomplished was when I was a warehouse manager. I started a customer advocacy program where each lift operator owned a client. The energy of having direct customer/supplier contact to clarify shipping issues that transcended orders was an unmeasurable, and wonderful benefit. I close my eyes and imagine how much easier my life as a customer service manager, warehouse manager or transportation manager would have been if I could have broadened the knot on my bowtie. Then I laugh…. I am imagining the discussions with the union steward to prep for the training and helping the organization to become an open organization. It makes me ponder. While we have technologies, can we ever break the barriers to truly build collaborative relationships and broaden the knot on our bow ties to build long-lasting supply chain relationships: people to people?

What do you think? Any tips to share on how you have broadened your bowtie?

This week I am off to help a client with Sales and Operations Planning. You will find me blogging on Delta go-go at the end of the week. Look for my insights.

I am also close to publishing two reports: Overview of Sales and Operations Planning Technologies and the Rise of Social Commerce. <I do the most writing on the plane.>