I spent my summers as a lifeguard. To certify, I had to tread water for what seemed like an incessant period of time. In reality it was only two minutes, but as a teenager it seemed like a very looooooong time.

I spent my summers as a lifeguard. To certify, I had to tread water for what seemed like an incessant period of time. In reality it was only two minutes, but as a teenager it seemed like a very looooooong time.

To tread water a swimmer uses their arms and legs to keep their body in a vertical position and maintain the status quo. While there are many ways to tread water, they are all tiring.

Treading Water in the Real World: Managing Costs for the Supply Chain Leader

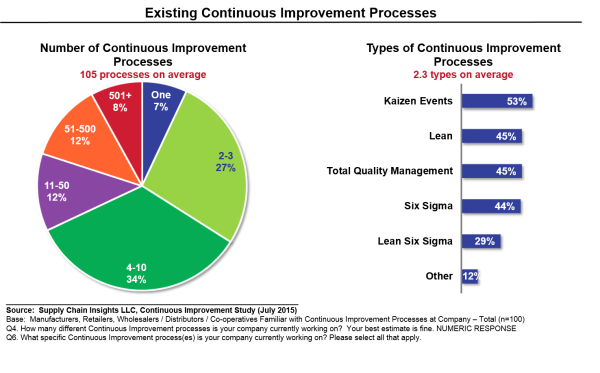

In a large company the average supply chain leader manages hundreds, even thousands, of cost reduction programs simultaneously. The issue is that many of these projects and programs are disconnected. In Figure 1 we share some recent survey results.

Figure 1. Continuous Improvement Processes

There are many techniques–Lean, Six Sigma, Total Quality Management–but, the overarching focus is on managing and reducing costs.

Over the last decade managing costs in the supply chain has become more and more difficult. Only 12% of public companies are making improvement during the period of 2009-2015 in both operating margin and inventory despite spending an average of 1.7% of revenues on Information Technology (IT).

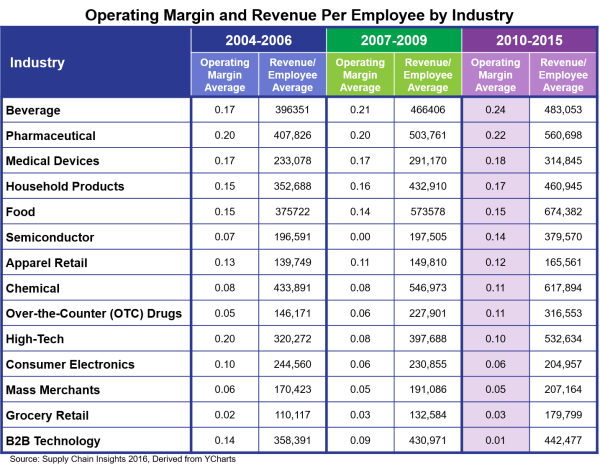

With all of the current political rhetoric on jobs and efficiency, we thought that it would be an interesting exercise to evaluate and contrast the state of industries pre-recession, during the recession and post-recession. Shown in Table 1 are operating margin, and revenue per employee averages for the three periods by industry subsegment. Nine of the 14 industry groups improved operating margin while 13 of the 14 industries improved revenue per employee. The globalization of the supply chain, along with outsourcing and automation, is dramatically reducing the requirement for labor. It was easier to reduce labor in the early part of the decade. Post-recession versus pre-recession labor inputs declined by 45% while the more recent comparison is only a 19% labor improvement.

Table 1. Operating Margin Revenue Per Employee for Three Time Periods by Industry Subsegment

I am a self-professed data geek. I love spreadsheets.

So what does this mean? Treading water is hard. Operating cost reduction is getting harder and harder. In some industries, like Apparel Retail, B2B Technology, Consumer Electronics, Hi-Tech, and Mass Merchants, we are going backwards.

The struggle lies before us. The tension is on jobs, productivity and brand integrity. While the supply chain of the past focused on the reduction of manual labor, the future of the autonomous supply chain will require even fewer people in white-collar positions. I believe that 80-90% of planning jobs will be eliminated and that there will be substantial cuts in the workforce for distribution and manufacturing through robotics. There will be new positions that will result in the need to reskill and train workers, but these will be very specialized positions.

The Future for the Supply Chain Leader?

In summary, I think that the supply chain leader can no longer afford to tread water. Instead, I think it is time to swim upstream to another pool. This can only happen through the development of new and innovative processes. I would love your thoughts.